Plasma & Flame Treatment Prepares Aluminum Surfaces for Bonding

Bonding to aluminum can be major challenge. Engineers typically rely on adhesives to bond aluminum without welding. Depending upon application requirements, there are several adhesives and VHB foam tapes that have proven effective. However, all adhesive-based remedies are subject to failure if surface preparation is overlooked. Aluminum Surface Contaminates Aluminum is often annealed to achieve…

Read MoreWhat Plasma Actually Does to a Surface to Improve Adhesion

Air plasma surface treating is an emerging green technology for leading manufacturers tasked with assembling and decorating plastics, composites, glass and metals. It is a powerful, yet relatively inexpensive technology that is used by both Fortune 100 companies and small operations to improve bond strength, product quality and throughput. You can see the effects of…

Read MoreIs Plasma Treating the Missing Link in Your Adhesive Bonding Operations?

To enable adhesive bonding, manufacturers rely on primers, cleaners, chemical etching & mechanical roughening. However, these traditional surface preparation methods are notorious for limiting productivity & product quality for the following reasons: Use of in-line plasma & flame surface treating is on the rise because it solves these challenges by cleaning, etching & functionalizing surfaces…

Read MoreHow Automotive Manufacturers use Plasma & Flame to Improve Quality & Efficiency

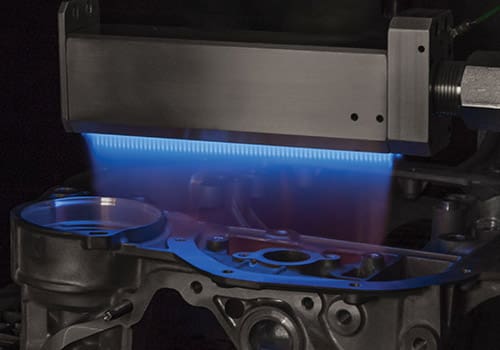

Plasma & Flame surface treating technologies are helping suppliers in the automotive industry reduce cost, improve quality, and maximize production efficiencies. Projects for vehicle lightweighting, decorating, gasket sealing adhesion, and electrical potting are fueling the need for incorporating plasma and flame surface treaters. This 45-minute webinar provides insights on how treatment improves adhesion for assembling,…

Read MoreMedical Device Engineer’s Guide for Improving Adhesion with Atmospheric Plasma

As joining of medical plastics is becoming more complex and sophisticated in performance specifications and structural complexity, surface treatment is an integral part of medical assembly processes. This 30-minute webinar, Enercon and BTG Labs provide insights into the capabilities of atmospheric plasma treatment systems and how medical device engineers can use these technologies and surface…

Read MoreTroubleshooting Adhesive Bonding Failures

When it comes to your health, where you go for help can determine the remedy. A surgeon might lean toward surgery, a pharmacist might suggest a new prescription, and a life coach might recommend lifestyle changes. Likewise, when you have an adhesive bonding failure getting insights from an adhesive supplier, a surface characterization solutions provider and…

Read MoreImprove Adhesion Results with New Scientific Diagnostics & Surface Treating

Plasma & flame surface treaters clean, etch and functionalize surfaces to improve bonding with adhesives, inks, coatings and paints. Dyne level and contact angle are commonly used to measure treatment effectiveness. Today, new automated scientific diagnostics are used to identify a more useful measurement: surface free energy, including polar and dispersive components. Experts on surface…

Read MoreWhy Manufacturers Use New Flame Technology to Improve Adhesion

Advances in flame surface treatment technology are fueling a renewed interest in flame as an automated method of improving surface adhesion. Today’s flame treaters are remarkably safe, reliable & effective at treating a wide variety of plastic, composite, metal and paperboard surfaces. Discover why flame is an ideal solution for high line speeds, complex surface…

Read MoreHow New Plasma Treating Technology is Advancing Adhesion Dependent Manufacturing Processes

The new Blown-ion™ Plasma Treater offers manufacturers powerful and uniform surface treatment for improving adhesion at high processing rates. This plasma treater utilizes a wide MultiPort™ head design that bombards surfaces with an intense, high-speed discharge of ions to clean, etch & functionalize surfaces. Treatment removes contaminants, increases bonding sites, & improves the wettability of…

Read MoreHow Plasma and Flame Surface Treating Improve Adhesive Bonding

It’s well-known that surface preparation can improve and enable adhesive success. Abrasion, chemical, degreasing and physical surface preparation methods are often used to support better bonding. In-line plasma and flame surface treating are gaining in popularity for their ability to clean, etch and functionalize surfaces. Their capacity to provide consistent and repeatable performance as part…

Read More