PLASMA TREATING Featured Press Releases

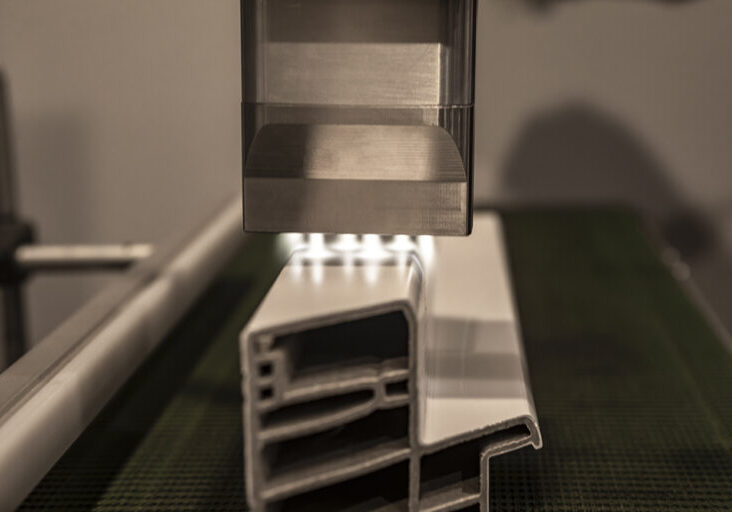

Automotive Parts Supplier Eliminates Hazardous Adhesion Promoter with Enercon Plasma Treating Technology – Saves $850,000, Improves Productivity & Quality while creating a Safer Work Environment.

LEARN MORE All Press Releases

Filter by Application

Filter by Technology

Filter by Materials

Filter by Subcategory

Mike McConnell Promoted to Vice President of Sales

Enercon is pleased to announce that Mike McConnell has been promoted to Vice President of Sales, overseeing Enercon’s surface treating and cap sealing sales teams. “In a few short years,...

Video Showcases Founding Principles & New Corporate Headquarters in the Words of Enercon Employees

Enercon Industries Corporation is pleased to release a new video which gives the industry an inside look at the company’s 50-year journey in becoming the leading induction cap sealing and...

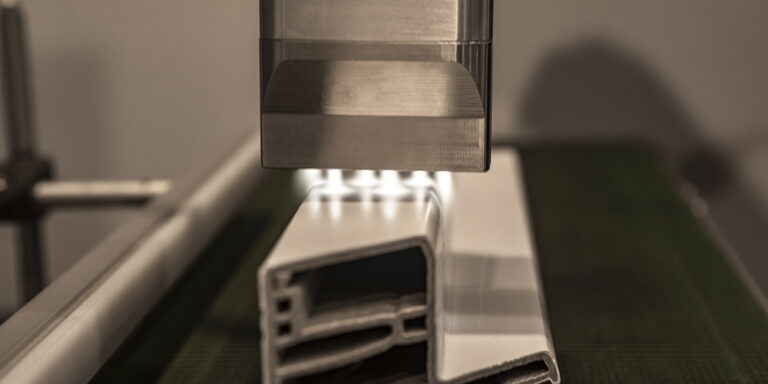

Enercon Offers the Widest Range of Surface Treating Technologies at NPE

Get your chance to see the industries’ most comprehensive platform of PLASMA, FLAME & CORONA surface treating technologies in the FRONT ROW of NPE’s West Hall (Booth W6643). (Get your...

Enercon to Open New Corporate Headquarters

Enercon Industries Corporation is pleased to announce it is constructing a new facility to meet the demands of its growing customer base. The facility creates additional manufacturing capacity, enhances customer...

Ryan T. Schuelke Promoted to President / Chief Sales Officer of Enercon Industries Corporation

Enercon Industries Corporation is pleased to announce the promotion of Ryan T. Schuelke to President / Chief Sales Officer. The promotion expands Schuelke’s responsibilities which as Chief Sales Officer includes...