Enercon Unveils Plasma & Flame Surface Treating Laboratory to Advance Adhesion Innovation

Enercon proudly announces the opening of its new Surface Treating Laboratory, a cutting-edge facility designed to demonstrate and develop the latest advancements in atmospheric plasma and flame surface treatment. “As the surface treating technology leader, Enercon offers the industry’s greatest variety of Blown-arc™, Blow-ion™ & Multiport™ plasma & flame surface treaters. With this new lab,…

Read MoreChampion Plastics Uses Plasma Treating to Improve Automotive Process

Champion Plastics wins an innovation award for their creative line upgrades in supplying General Motors with a TPV (thermoplastic vulcanisate) seal, for fuel efficiency. Watch the in-line plasma treater in operation.

Read MoreChoosing the Best Surface Treatment Technology: Plasma vs. Flame

Surface treatment technologies, including plasma and flame, play a pivotal role in enhancing adhesion, improving surface energy, and enabling efficient and repeatable manufacturing processes. Choosing between these technologies depends on the materials being treated, application speed, and system integration. In this guide, we’ll break down the key differences, benefits, and practical considerations to help you…

Read MoreWhy Plasma Surface Treatment Is Critical for High-Quality Inkjet & Pad Printing

When it comes to achieving reliable ink adhesion with direct-to-product printing, the secret is on the surface. The printing on your products tells a story, and achieving flawless results requires more than just the right printing equipment and high-quality ink. Surface preparation plays a starring role in bringing those vibrant visions to life. Plasma surface…

Read MorePrevent Adhesion Related Warranty Claims with Plasma & Flame Surface Treatment

Failed adhesion costs manufacturers millions of dollars in warranty claims every year. The root cause is often inadequate surface preparation. In this new webinar, find out how leading automotive manufacturers solve adhesion-related warranty issues by improving their production processes with plasma & flame. Insights for Webinar Attendees: Find out how you can determine if automating…

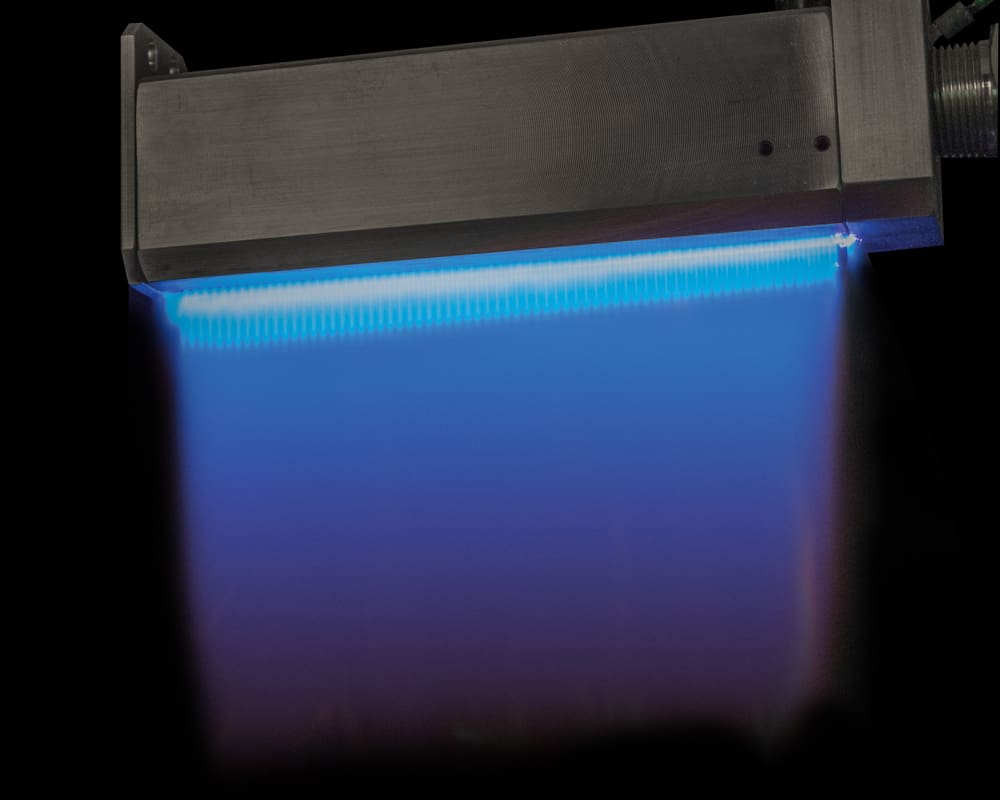

Read MoreEverything You Need To Know About Flame Surface Treatment

The Key to Stronger, More Reliable Adhesive Bonds: Flame Treatment One of the most important requirements for adhesion is the condition of the surface prior to bonding with inks, coatings and adhesives. Fortunately, there are technologies which can be used to modify surfaces to make them more receptive to bonding. One of the oldest surface…

Read MoreHow an Automotive Manufacturer Greatly Reduced Warranty Claims by Switching to Plasma Treatment

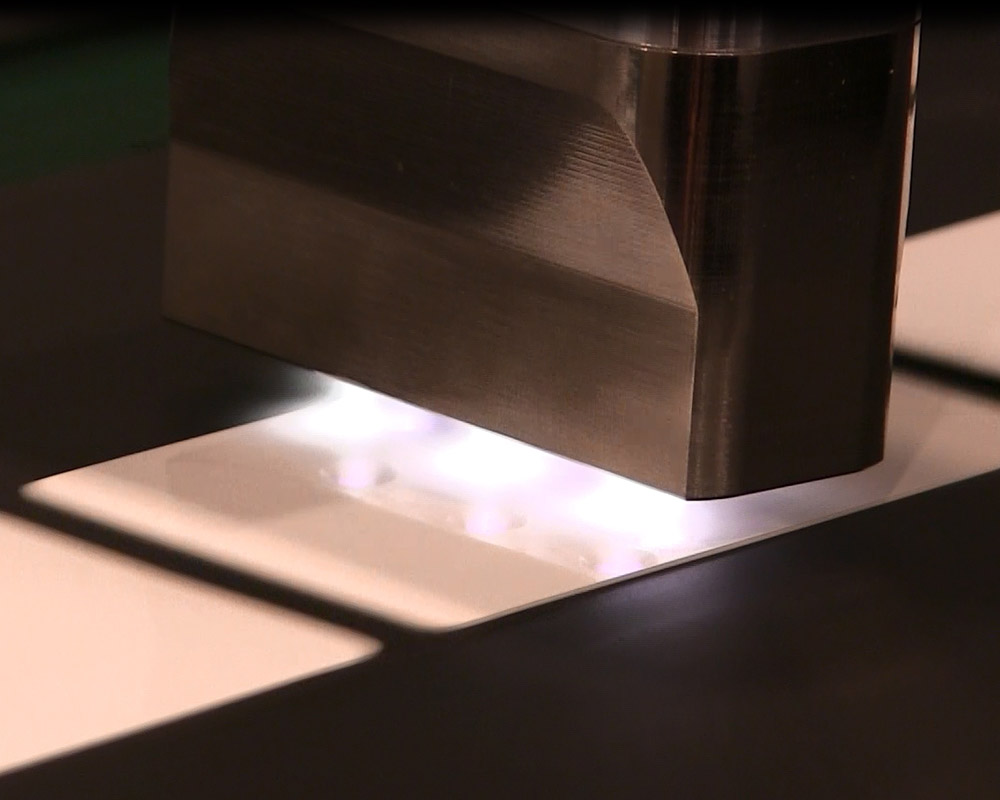

By implementing Blown-ion plasma treatment prior to adhesive bonding operations on a Formed-in-Place-Gasket, this manufacturer significantly reduced warranty claims. Plasma works to clean, etch and functionalize a surface to enhance surface energy and create a much better bond with adhesives. Watch Enercon’s Blown-ion Plasma Treaters in action!

Read MoreAutomotive Manufacturer Reduces Warranty Claims with Plasma Treating (Video Included)

A major automotive manufacturer is reaping the benefits of reduced warranty claims by implementing plasma treating into their adhesive bonding operations. This specific application is for creating a Formed-in-Place Gasket (FIPG). FIPG is a process that creates a seal between two surfaces by applying a liquid sealant between them. The quality of the adhesive bond…

Read More5 Mistakes to Avoid When Plasma or Flame Treating Surfaces

When properly implemented, plasma and flame surface treating can improve bonding with adhesives, coatings and inks. However, there are a number of common mistakes made when evaluating and integrating surface treaters that can easily be avoided. In this new webinar, Enercon shares insights on mistakes that can undermine your success: Fill out the form to…

Read MoreNew eBook Offers Technical Insights on using Atmospheric Plasma

Enercon is excited to announce the release of a new eBook: Getting Started with Plasma Surface Treatment. This free eBook provides engineers and manufacturers with a comprehensive guide on how plasma surface treating technology is used to improve bonding for a wide variety of industrial applications. This interactive resource will equip readers with foundational knowledge…

Read More