LEARN MORE All Technical Articles

Filter by Application

Filter by Technology

Filter by Material

Filter by Subcategory

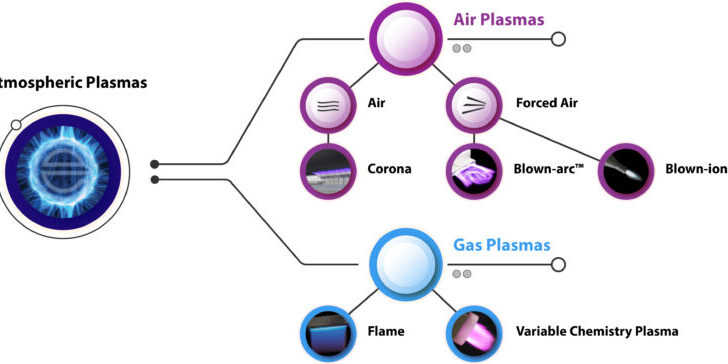

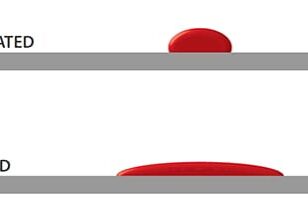

Corona vs. Plasma

Enercon receives many questions about the differences and similarities between corona and plasma surface treating. In all cases, the context of the question is very important as some industries have...

Three Mistakes to Avoid When Plasma Treating

We have many customers who have tried a corona or plasma treating solution in the past with failed results and were very hesitant to give plasma a second try. However,...

Henkel Adhesives & Enercon Plasma Treatment Case Study:

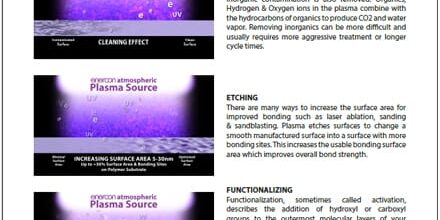

Surface Treatment Effects on Adhesive Bond Strength Henkel and Enercon Industries partnered in this study to compare the effects of adhesives’ bond strength on fluoropolymers when they are pre-treated with...

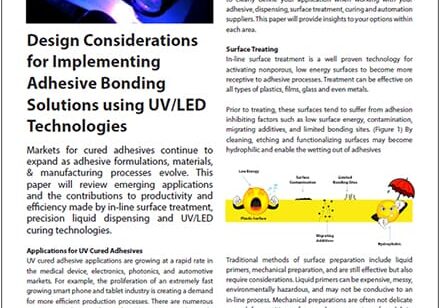

Design Considerations for Implementing Adhesive Solutions using UV/LED Technologies

Markets for cured adhesives continue to expand as adhesive formulations, materials, & manufacturing processes evolve. In this paper, industry experts discuss the latest technology being used in medical, optics, plastics,...

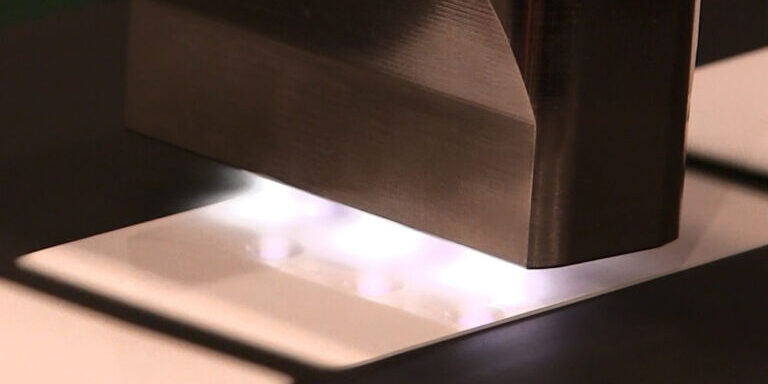

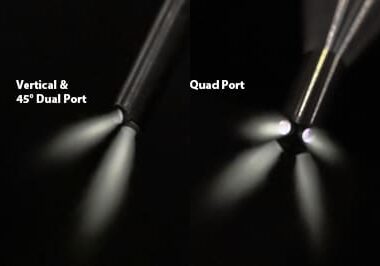

Unique and Custom Plasma Treating Designs for Difficult to Reach Surfaces

Enercon’s Blown-ion™ plasma discharge heads are well known for their ability to improve surface adhesion with inks, adhesives and coatings. They can be integrated in with robotics, indexing systems and conveyor systems...

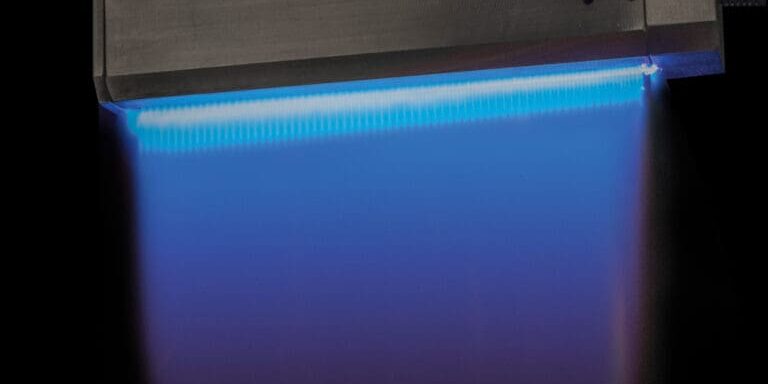

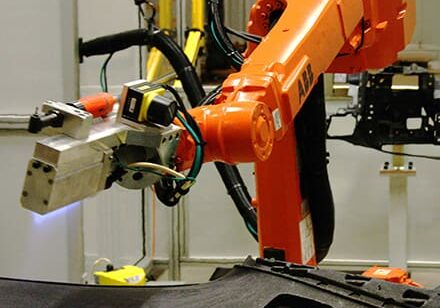

Custom Integrated Conveyor Systems for Flame Treating Applications

Enercon flame treating systems can be integrated in a variety of configurations based on each application's requirements. In many cases, the flame is integrated with a robot so the flame burner can...