Enercon Unveils Plasma & Flame Surface Treating Laboratory to Advance Adhesion Innovation

Enercon proudly announces the opening of its new Surface Treating Laboratory, a cutting-edge facility designed to demonstrate and develop the latest advancements in atmospheric plasma and flame surface treatment. “As the surface treating technology leader, Enercon offers the industry’s greatest variety of Blown-arc™, Blow-ion™ & Multiport™ plasma & flame surface treaters. With this new lab,…

Read MoreChampion Plastics Uses Plasma Treating to Improve Automotive Process

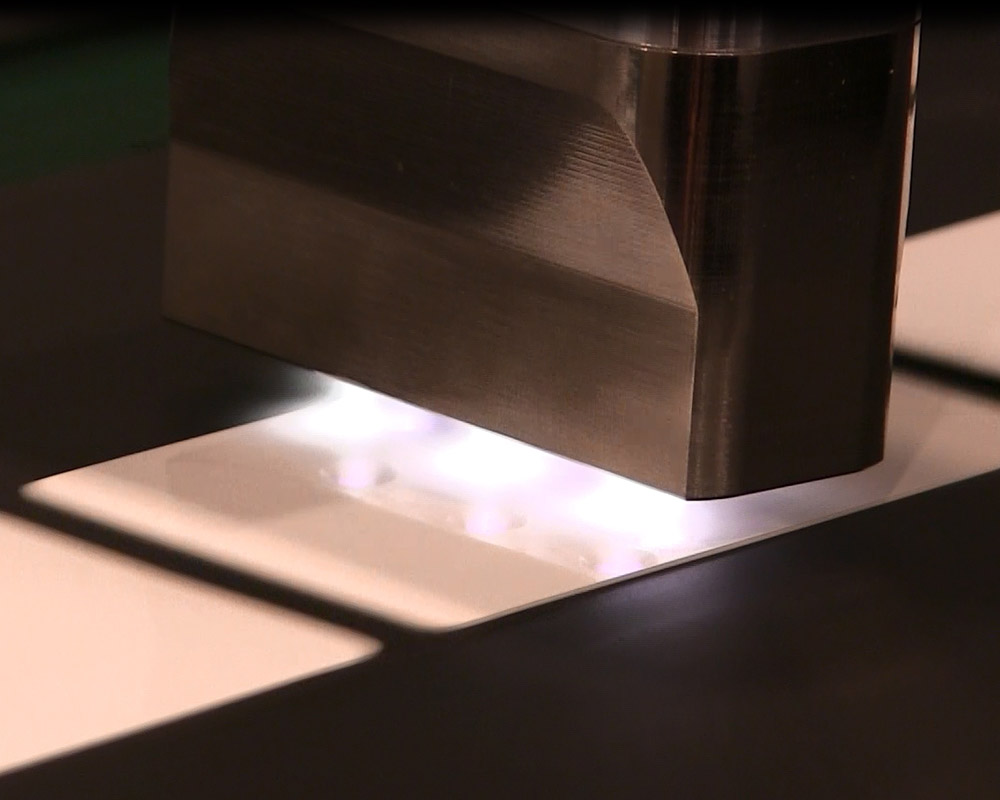

Champion Plastics wins an innovation award for their creative line upgrades in supplying General Motors with a TPV (thermoplastic vulcanisate) seal, for fuel efficiency. Watch the in-line plasma treater in operation.

Read MoreWhy Plasma Surface Treatment Is Critical for High-Quality Inkjet & Pad Printing

When it comes to achieving reliable ink adhesion with direct-to-product printing, the secret is on the surface. The printing on your products tells a story, and achieving flawless results requires more than just the right printing equipment and high-quality ink. Surface preparation plays a starring role in bringing those vibrant visions to life. Plasma surface…

Read More5 Mistakes to Avoid When Plasma or Flame Treating Surfaces

When properly implemented, plasma and flame surface treating can improve bonding with adhesives, coatings and inks. However, there are a number of common mistakes made when evaluating and integrating surface treaters that can easily be avoided. In this new webinar, Enercon shares insights on mistakes that can undermine your success: Fill out the form to…

Read MoreMyths and Mysteries of Measuring Dynes, Surface Free Energy & Contact Angle

Since plasma and flame surface treatment create no visible changes to a surface, methodologies have been developed to measure the changes to a surface after treatment. These diagnostics are quite valuable, but they are often conducted with flawed testing practices and the results are frequently misunderstood. In this new webinar, experts from Enercon & KRÜSS…

Read MoreAtmospheric Plasma and Flame Surface Treatment for Medical Applications

Get insight on how medical device manufacturers are using atmospheric plasma to eliminate adhesion challenges. What’s in the eBook? Learn how atmospheric plasma is helping users improve product quality, and increase production speeds. See what Enercon customers are saying “For medical printing applications, it’s imperative to follow the defined protocols. Enercon’s experience with medical device…

Read MoreContinuous Inkjet Printing for Industrial Manufacturing Applications

As a non-contact printing process, inkjet offers manufacturers tremendous production advantages including variable data, fast changeover and reliability at top line speeds. Applications abound for plastics and rubber in the wire & cable, packaging, coding & industrial manufacturing industries. However material properties, surface contamination, ink/material compatibility and durability requirements create challenges. Keys for successful ink…

Read MoreTop 3 Strategies to Improve Your Adhesive Bonding Operations

Production & design engineers are challenged with developing manufacturing processes that yield optimal results for quality and throughput. Since many do not fully understand the chemistry aspects of interfacial surface adhesion, they rely on conventional production methodologies, which ultimately undermines the repeatability of their success. In this new webinar, industry experts Wilson Lee (Enercon Industries)…

Read MoreImprove Adhesion in Window & Door Manufacturing Processes

Learn how plasma & flame surface treatment are used to efficiently create strong bonds for the assembly, painting and decorating of windows and doors. Discover how these technologies work, see examples of specific industry applications, and get insights from the application experts at Enercon. Plus, gain access to info on our new plasma treating nozzles which are…

Read MoreIs Plasma Treating the Missing Link in Your Adhesive Bonding Operations?

To enable adhesive bonding, manufacturers rely on primers, cleaners, chemical etching & mechanical roughening. However, these traditional surface preparation methods are notorious for limiting productivity & product quality for the following reasons: Use of in-line plasma & flame surface treating is on the rise because it solves these challenges by cleaning, etching & functionalizing surfaces…

Read More