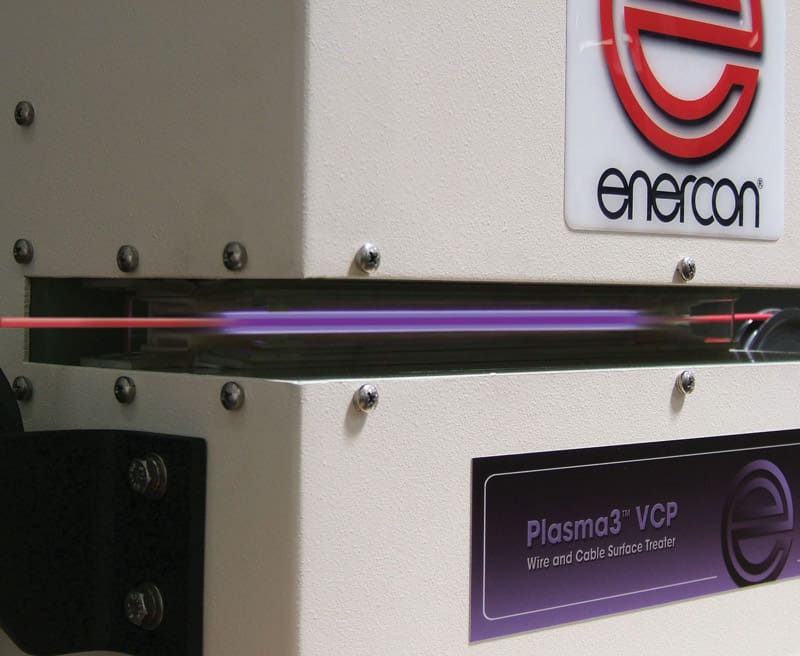

Plasma3™ VCP Atmospheric Plasma Surface Treatment

Plasma3™ VCP uses variable chemistry to plasma treat surfaces that would otherwise be unresponsive to air plasma surface treatment.

This powerful yet gentle treatment system successfully cleans, etches and otherwise functionalizes a wide range of materials. It has been specifically designed for treating either sheets, boards or objects with minimal contour such as tubing and wire. For webs and rolled goods Enercon offers the Plasma3™surface treating system.

The ability to produce long lasting treatment results on materials that would be otherwise unresponsive is one of the major advantages of Plasma3™ VCP. However its ability to clean, etch and functionalize surfaces has made Plasma3™ VCP a breakthrough solution for many industry leading firms.

Added benefits include treatment for both conductive and non conductive surfaces. And, when your application changes, you can take advantage of the system's limitless variable chemistry capabilities.

How Plasma3™ VCP works

Reactive gases are diffused toward the surface under the influence of electrical fields. Low molecular weight materials such as water, absorbed gases and polymer fragments are knocked off the surface to expose a clean, fresh surface. At the same time a percentage of the reactive components in plasma with sufficient energy bond to the freshly exposed surface, changing the chemistry of the surface and imparting the desired functionalities.

Become one of the leading companies in your industry by leveraging this new technology into your product development plans. To get you started we offer convenient Plasma3™ VCP trials in our surface treatment laboratory. Be sure to watch our Flash animation of the Plasma3™ treating process.

Enercon systems are designed to operate in a maximum ambient temperature of 40°C (104°F) @ 80% relative humidity, non-condensing.

CLEAN, ETCH, & FUNCTIONALIZE Why choose Enercon atmospheric plasma systems?

-

Application Expertise

- Thousands of surface treating trials on hundreds of unique materials

-

Field Proven

- More than 100 atmospheric plasma systems in operation around the world

-

Patented Technology

- Unique multi-patent earning design

-

Extensive Lab Capabilities

- Unbiased comparison of treatment technologies

-

Manufacturing Experience

- Benefit from over 30 years design, engineering and manufacturing

-

Impeccable Reputation for Quality

- Reliable production grade equipment you can count on

-

Global Perspective & Local Support

- Direct personnel and major operating centers throughout the world (Brazil, Korea, India, Japan, Singapore, United Kingdom, United States) are staffed with knowledgeable application engineers and critical replacement parts