Enercon Unveils Plasma & Flame Surface Treating Laboratory to Advance Adhesion Innovation

Enercon proudly announces the opening of its new Surface Treating Laboratory, a cutting-edge facility designed to demonstrate and develop the latest advancements in atmospheric plasma and flame surface treatment. “As the surface treating technology leader, Enercon offers the industry’s greatest variety of Blown-arc™, Blow-ion™ & Multiport™ plasma & flame surface treaters. With this new lab,…

Read MoreChoosing the Best Surface Treatment Technology: Plasma vs. Flame

Surface treatment technologies, including plasma and flame, play a pivotal role in enhancing adhesion, improving surface energy, and enabling efficient and repeatable manufacturing processes. Choosing between these technologies depends on the materials being treated, application speed, and system integration. In this guide, we’ll break down the key differences, benefits, and practical considerations to help you…

Read MoreWhy Plasma Surface Treatment Is Critical for High-Quality Inkjet & Pad Printing

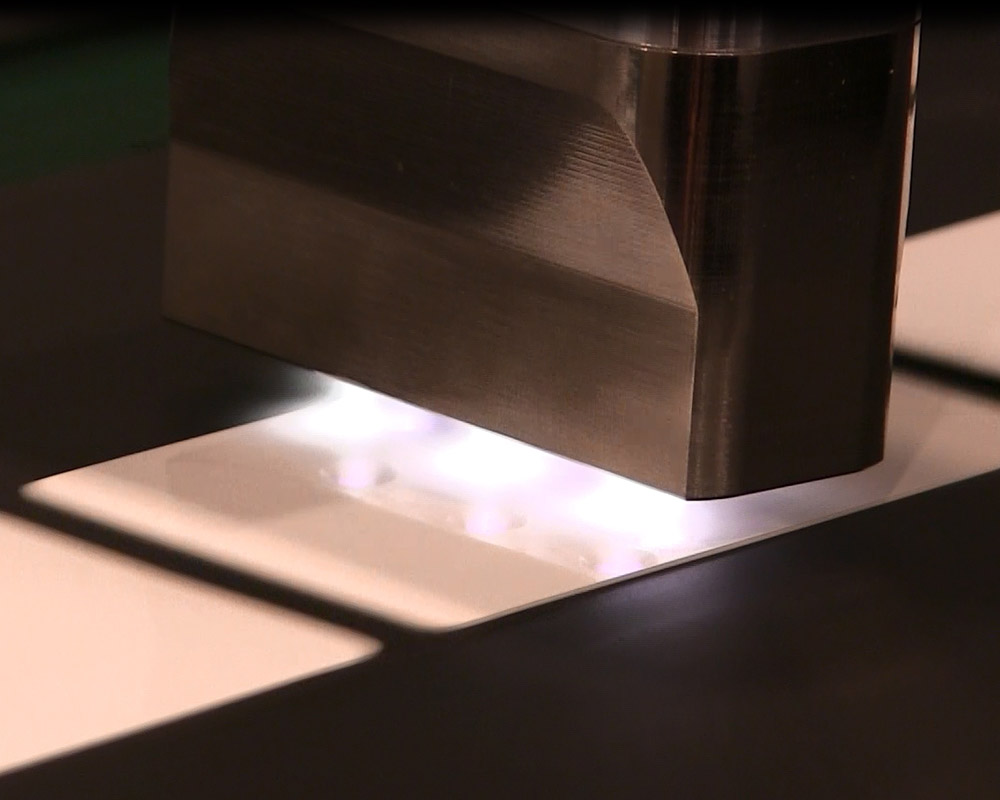

When it comes to achieving reliable ink adhesion with direct-to-product printing, the secret is on the surface. The printing on your products tells a story, and achieving flawless results requires more than just the right printing equipment and high-quality ink. Surface preparation plays a starring role in bringing those vibrant visions to life. Plasma surface…

Read MoreEverything You Need To Know About Flame Surface Treatment

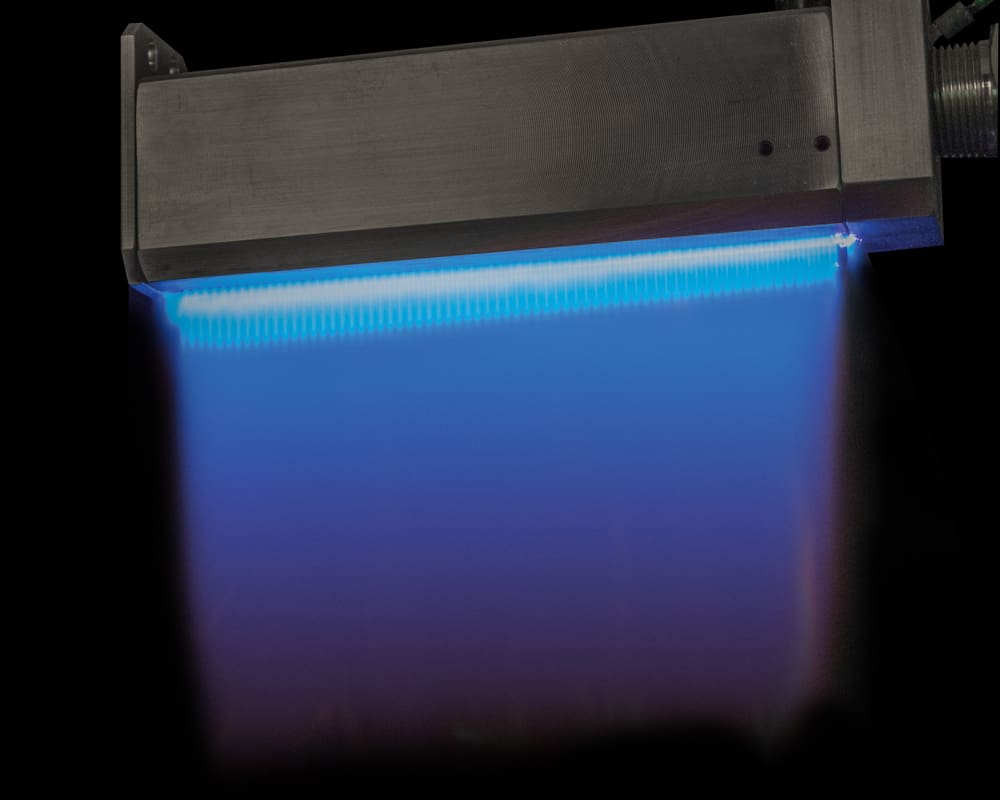

The Key to Stronger, More Reliable Adhesive Bonds: Flame Treatment One of the most important requirements for adhesion is the condition of the surface prior to bonding with inks, coatings and adhesives. Fortunately, there are technologies which can be used to modify surfaces to make them more receptive to bonding. One of the oldest surface…

Read More5 Mistakes to Avoid When Plasma or Flame Treating Surfaces

When properly implemented, plasma and flame surface treating can improve bonding with adhesives, coatings and inks. However, there are a number of common mistakes made when evaluating and integrating surface treaters that can easily be avoided. In this new webinar, Enercon shares insights on mistakes that can undermine your success: Fill out the form to…

Read MoreNew eBook Offers Technical Insights on using Atmospheric Plasma

Enercon is excited to announce the release of a new eBook: Getting Started with Plasma Surface Treatment. This free eBook provides engineers and manufacturers with a comprehensive guide on how plasma surface treating technology is used to improve bonding for a wide variety of industrial applications. This interactive resource will equip readers with foundational knowledge…

Read MoreNew Plasma & Flame Treater Head Designs Improve Treatment Coverage, Integration and Efficiency

Manufacturers look to Enercon to solve adhesive, ink & coating challenges. Many of these applications require a unique or custom engineered solution. This is where our plasma & flame treating experts work their magic. In this exclusive webinar, we share our most recent groundbreaking surface treater designs that enable plasma & flame to overcome integration…

Read MoreNew Blown-ion™ 500 Plasma Surface Treating Technology Enables Rockwell Automation’s Switch from Print-and-Apply Labels to In-Line Digital Printing

When Rockwell Automation moved its contactor and relay production back to Milwaukee, Wisconsin, it had to develop an entirely new process for the changing volumes and available space. The new highly automated assembly line would also be a showcase of Rockwell’s automation capabilities, featuring Rockwell drives, motors, Independent Cart Technology (ICT), PLC’s, HMI’s, sensors, and…

Read MoreHow and why plasma and flame surface treating improve surface adhesion.

Common adhesion impediments found on surfaces. Non-porous and hydrophobic surfaces have low surface energy with few available bonding sites due to low levels of charged ions on the surface. Additionally, any type of surface contamination affects adhesion negatively. This contamination can include material additives & release agents which can migrate to the surface. Clean, Etch…

Read MoreGetting Started with Flame Plasma

What’s in the eBook? Learn how flame plasma is helping users improve product quality, and increase production speeds. See what Enercon customers are saying “We’ve integrated Enercon flame treaters and we really enjoy working with Enercon because of their depth of knowledge in surface treating.”Jerry Schmit, Sr Applications Engineer, Midwest Engineering Solutions

Read More