Blame the Corona Treater

The Truth about Dyne Levels, Watt Density & Adhesion When inks, coatings, adhesives and laminations don’t bond with substrates, converters are quick to blame the corona treater. And why shouldn’t they? Corona treaters are responsible for adhesion, right? Well, not exactly. This article looks into the relationship between the corona treater and adhesion. We’ll dive…

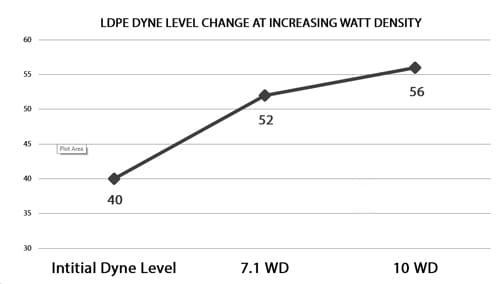

Read MoreCan you use Watt Density to Predict Dyne Levels?

The ultimate goal of any surface treatment system is to increase surface tension measured in dynes which then increases the wettability and adhesion characteristics of the surface. This allows you to add value to the substrate through printing, laminating, coating etc.. Corona treating systems achieve this by applying a given level of power over a…

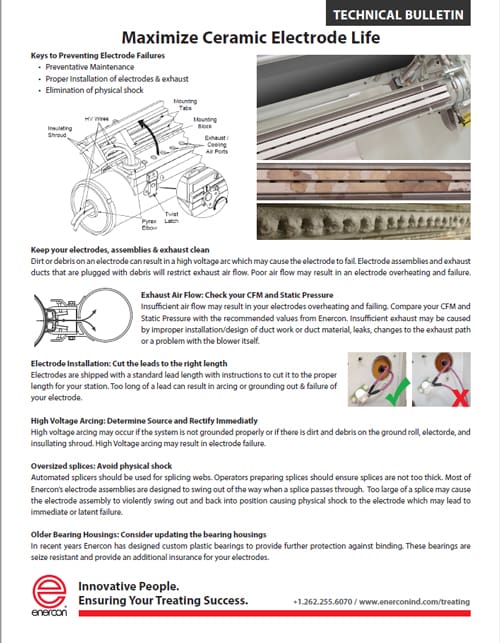

Read MoreTips for maximizing the life of your ceramic electrodes

Ceramic electrodes are used extensively in the converting industry for creating corona to improve the surface energy of conductive and nonconductive films and foils. These rugged electrodes are designed to survive the cauldron of heat, ozone and electrical discharge created by the corona treating process. To ensure the electrodes continue to perform as designed operations…

Read MoreWhy All Films Do Not Treat the Same

The Signature Relationship Between Your Film and Corona Treaters How well do you understand the relationship between your films and your corona treater? A treatment level of 2.0 watt density yields very different results on PET compared to Polypropylene. And, a nominal change in watt density can produce unexpected results. This paper looks at the…

Read MoreTroubleshooting Surface Treating for Flexographic Printing Process

Want to learn more about your flexographic printing process? Want your operators to have more control over the press? Then learn the power of asking “why”. Three letters that add up to a powerful and revealing question. When we were three and four years old, it was our favorite question. It often stymied Mom and…

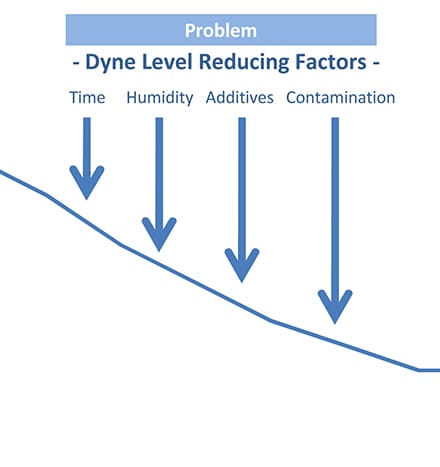

Read MoreTroubleshooting Dyne Levels for Cast and Blown Film Lines

“That film you sent me was supposed to be 42 dynes! I can’t convert this stuff and I’ve got orders due!!!” exclaims the exasperated converter. “Hold on a minute, I’m sure we shipped you film that was 42 dynes, let me look into this,” contends the film producer. When dyne levels are insufficient, it’s a…

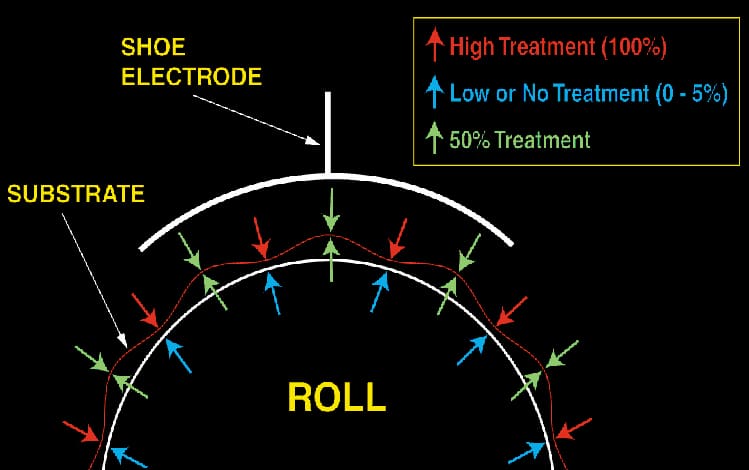

Read MorePrevent Backside Treatment

The bad news is that backside treatment mitigates the effects of surface treating. In some cases, it results in under treatment of substrates. It can also raise the energy of the backside surface creating processing problems. In bag making and seal applications, backside treatment can alter the substrate’s co-efficient of friction. This will ultimately cause…

Read MoreExtrusion Coating Adhesion Benefits With Ozone

Abstract Ozone application to an extrudate web has been used for over a decade to enhance adhesion of polymer to the substrate in the extrusion coating process. However, to date, ozone’s effectiveness has not been quantified by published statistical data. A two-level fractional factorial design consisting of 64 experimental runs was utilized to study the…

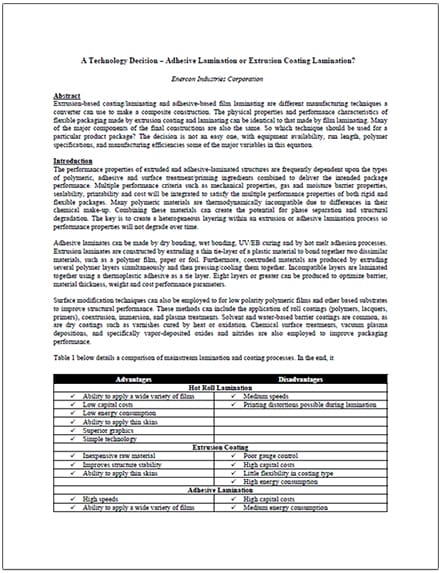

Read MoreA Technology Decision – Adhesive Lamination or Extrusion Coating/Lamination?

Read the abstract below and download your copy of this informative technical paper which was presented at the TAPPI PLACE 2010 conference presentation “A Technology Decision – Adhesive Lamination or Extrusion Coating/Lamination?”. Abstract Extrusion-based coating/laminating and adhesive-based film laminating are different manufacturing techniques a converter can use to make a composite construction. The physical properties…

Read More