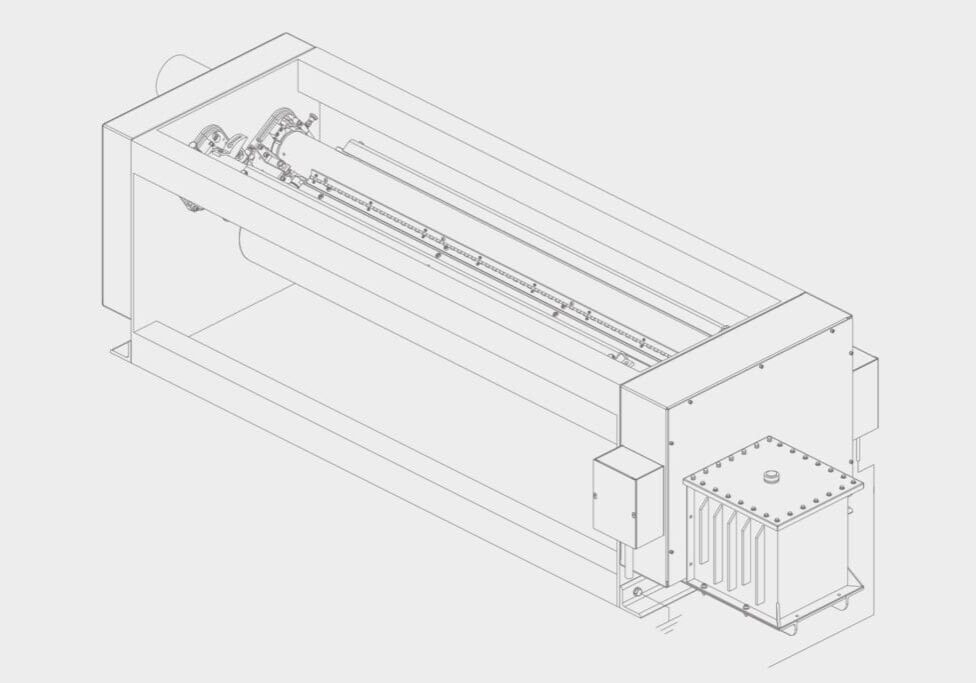

Corona Treaters for Blown & Cast Film Extrusion Lines

For variable & fixed width corona treating of polymer films at the time of extrusion Enercon’s line up of metal electrode corona treaters with covered ground rolls are the ideal choice for effective treatment & reliable performance.

Enercon’s application experts will configure your corona treater for the type of treatment needed, treatment power required, any OEM integration requirements, and other application criteria requiring special web handling features.

For fixed width treatment our ceramic electrode corona treaters, plasma & flame treaters are also available.

Contact us to see if Enercon's Performance Series™ or New Essential Series™ is right for your Blown Film operation.

Treatment options include fixed width, lane treating, skip & pattern treating

Common configurable components of a corona treater include the electrodes, the ground roll and the power supply.

Electrode Assemblies

Enercon’s CSO station design can be configured for all types of film extrusion surface treating applications. This well proven electrode assembly design offers several beneficial features.

Ozone & Thermal Protection:

Exhaust through electrode assembly removes ozone from the work area and cools electrodes to maintain thermal stability.

Splice Protection & Fast Thread-up:

Pneumatically actuated electrode assembly pivots out of the way.

Splice Pass-through:

Assembly pivots to protect electrodes from unexpected splices.

Easy Maintenance:

Hinged design enables easy clean-in-place maintenance.

Electrodes:

Fixed Width Treatment Bars or Rods: made from stainless steel to resist oxidation, these electrodes provide consistent treatment across the width of the electrodes.

Lane Treatment: Enercon's Performance Series™ offers stainless steel segmented electrodes featuring a positive push - pull locking mechanism for setting treat and no treat zones. Our Essential Series™ offers stainless steel flip segments for varying treat width.

Enercon systems are designed to operate in a maximum ambient temperature of 40°C (104°F) @ 80% relative humidity, non-condensing.

KEY FEATURES For Successful Blown & Cast Film Extrusion

-

Improve Surface Energy of Non-Conductive Films

-

Fixed Width, Segmented Lane & Pattern Treating

-

Stainless Steel Electrodes for Reliable Performance

-

Roll Covering Options: Silicone, Ceramic & More

-

Integrates with All OEM Lines

Our corona treaters integrate with all leading OEMs including Hosokawa Alpine, Bandera, Macro, Reifenhauser, & Windmoller & Holscher (W&H.)

RELATED CONTENT

OPTIONS Roll Coverings

-

Essential Series™ Silicone Roll Sleeve Roll Covering

Works well for most applications requiring low or moderate power levels. And now available with the patent pending Quick Sleeve™ Tool to rapidly replace silicone sleeves.

-

Performance Series ™ Conductive Ceramic Coating

Offers greater dieletric strength and durability for more demanding applications.

-

Other Coverings Available Upon Request

CORONA TREATING POWER SUPPLIES

Reliable industry workhorse for basic applications

Proven Reliability with Advanced Features

OPTIONAL EQUIPMENT Which may be recommended or specified:

-

Drive Packages

Tendency, Direct Drive, & Speed Matching

-

Idler Rolls

-

Network Communication

-

Nip Rolls

-

Spare Electrodes

-

Spare Parts Kit

-

Spare Rolls

-

Skip Treatment

-

Easy Thread