Optimize Inkjet Printing Adhesion for Wire & Cable Marking

Digital inkjet printing wire & cable provides manufacturers with productivity advantages including variable data, fast changeover & indelible printing at top line speeds. However, material properties, contamination, ink/material compatibility & durability requirements create challenges. Fortunately, a trilogy of suppliers has worked together to develop repeatable solutions for printing on a variety of substrates. This paper…

Read MoreDyne Level Does Not Guarantee Surface Adhesion

Dyne levels are a great indicator of your chance for adhesion success. But dyne level does not guarantee adhesion. Let’s look at a few factors that affect adhesion results. These include coating and material compatibility, surface energy, process variables, material variables and ultimately bonding requirements such as entanglement. Coating (ink, adhesive, paint, etc…) and material…

Read MoreHow Flame Control Systems Optimize Treatment

Flame is the world’s original surface treater and is commonly used on extrusion coating lines, paperboard processing and foil cleaning applications. If you haven’t considered a flame treater in some time you will be surprised at today’s advanced combustion control options and new high velocity burners that deliver effective and repeatable treatment. Managing the chemistry…

Read MoreFlame Treatment Automotive Dashboard to Improve Paint Adhesion Video

Enercon’s Flame Series surface treater treats an EVA automotive dashboard prior to painting. Treatment raise surface energy to promote paint adhesion. The flame treater is integrated with a robot that executes a treatment pattern based on a program actuated by a bar code scan on the part.

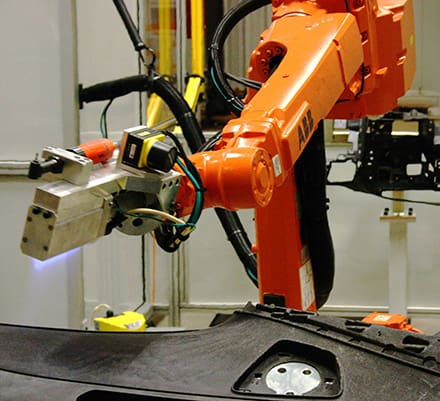

Read MoreRobotic Integration of Flame Treatment for Automotive Assembly Video

Enercon’s Flame treater is used by automotive manufacturers for a variety of applications such as bumpers, dashboards, consoles, glove boxes and air bags. The flame treater cleans the surface of contaminates to improve adhesion prior to applying an adhesive, paint or coating. For this project, Enercon’s Flame treater was integrated by MWES with an ABB robot. It…

Read MorePlasma Treatment on Nylon66 Increases Ink Adhesion Video

Learn how WAGO uses atmospheric plasma to improve ink adhesion, product quality, and productivity with Enercon’s Blown-ion™ atmospheric plasma surface treating. Watch the video and read the complete application story.

Read MoreSurface Treating Lab Samples Frequently Asked Questions Video

This video explains how easy it is to have Enercon test samples in our surface treating laboratory. Atmospheric plasma and flame treatment technologies are used to help you determine which solution is best for your application. Lab testing is a free service offered by Enercon. Surface Treaters are widely used to clean, etch and functionalize…

Read MoreWhat Plasma Treating Does to a Surface Video Animation

Plasma Treatment cleaning, etching and functionalizing Atmospheric plasma treatment is used by manufacturers, converters and packagers to improve surface energy and adhesion. The animations below show how the process effectively functionalizes surfaces. These treatment systems diffuse reactive gases toward the surface under the influence of electrical fields. Low molecular weight materials such as water, absorbed…

Read MoreHow Plasma & Flame Surface Treating Works – Explainer Video

Sam is a Quality Engineer at Stick-It Inc. and he is having trouble with the adhesive bonding and printing of his manufactured parts. The adhesives won’t stick and the ink rubs off! He needs to find a solution quick and decides to call Enercon for help. Follow Sam through his journey of discovering how plasma…

Read MoreEnercon Plasma Treater is a Game Changer for Biovation Labs’ FDA – Approved Packaging

Biovation Labs is an NSF 455-2 registered facility, providing their high-quality formulation, blending, encapsulation, tableting, and packaging. As a certified cGMP (Current Good Manufacturing Practices) facility, Biovation Labs takes pride in its manufacturing and packaging capabilities for all types of nutritional supplements. Their meticulous quality approach extends to every part of the operation, from the raw…

Read More