Optimizing Extrusion Coating Lines for Bio Resin Adhesion & Performance

Demand for sustainable packaging is forcing extrusion coating operations to add bio resin capabilities to their existing lines. While the principles of the extrusion coating process remain the same, the application variables presented by bio resins creates challenges in achieving proper adhesion and meeting production goals. In this new webinar, the surface treating experts at…

Read MoreThe Ten Commandments of Corona Treating Success

Gain insider knowledge and practical tips as we reveal the golden rules that distinguish companies achieving consistent, reliable corona treater performance from those that struggle with consistent results. In just one session, discover the critical factors that can transform your operations and ensure your equipment delivers peak performance every time. This new webinar succinctly covers…

Read MoreImprove Print Quality & Productivity by Controlling Substrate Surface Energy

Poor ink adhesion affects print quality, creates downtime, and leads to lost customers. In many cases, the cause is rooted in complications from the substrate surface. The good news is that surface variables can be eliminated with the proper use of a corona treater. A common misunderstanding is that pretreated films eliminate the need for…

Read MoreCorona Treatment For Extruded Film (Cast & Blown Film)

Most cast and blown film extruding applications are best served with a covered roll surface treater. Enercon offers two types of covered roll systems for extruding applications. Our original covered roll system is designed to meet the needs of the high-performance lines and our new blown film station capably handles the requirements of lower speed…

Read MorePromote Textile Desizing & Dyeability with Atmospheric Plasma

Textile manufacturers and end-users have been searching for ways to improve the surface properties of natural and synthetic fibers while minimizing the impact on the environment. The process of promoting pigment and dye uptake on textiles materials can involve priming agents to meet requirements for use, such as fade resistance, permanence under repeated laundering and…

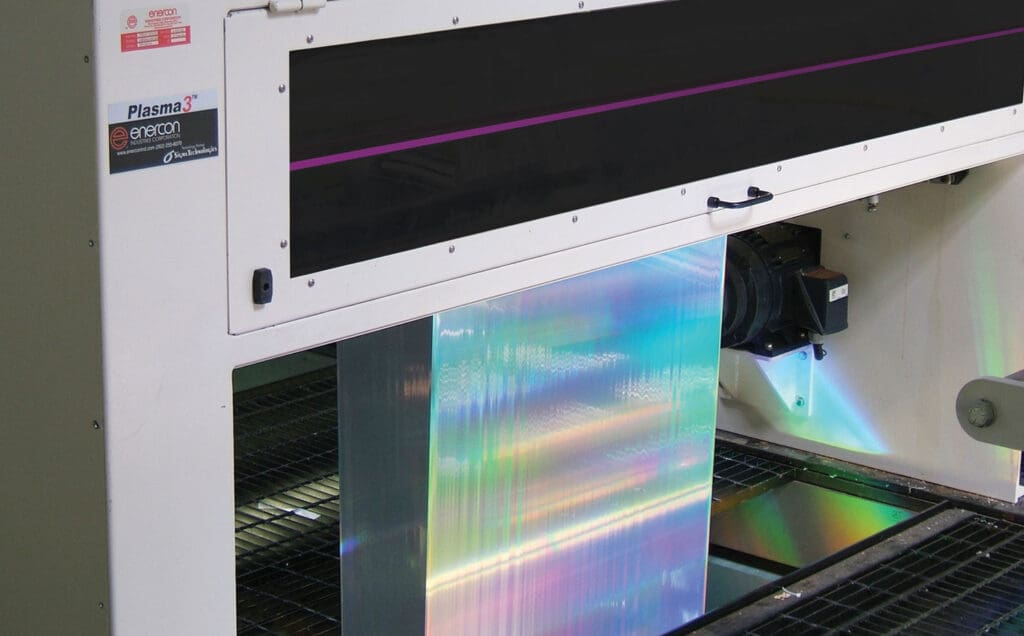

Read MoreMetallized Film Adhesion: Processing & Converting with Surface Treatment

Metallized film presents adhesion challenges to both film suppliers and converters. Today, new developments in surface treatment are creating competitive advantages by extending surface energy stability on metallized film. What metallized film converters should know Both the metallized film supplier and converter are at the mercy of the physics involved with dyne levels. Dyne level…

Read MoreImprove Lamination Adhesion with Surface Treating

For many industrial applications, the use of a single ply of a material does not provide all of the critical properties required for the optimal performance of a product. In these cases, a composite of two or more layers of material can provide this required performance. A common method of creating such a composite is…

Read MoreImprove Ink Printing Adhesion with Surface Treating

The task of optimizing printing adhesion can be difficult, primarily because of the many process variables which require control. The most critical of these parameters are 1) ink chemistry, 2) substrate quality, 3) surface treatment, and 4) ink transfer method. There are six major printing/decorating processes, each distinguished by the method in which ink and…

Read MoreExtruding Applications

Most cast and blown film extruding applications are best served with a covered roll surface treater. Enercon offers two types of covered roll systems for extruding applications. Our original covered roll system is designed to meet the needs of the high-performance lines and our new blown film station capably handles the requirements of lower speed…

Read MoreOptimizing Blown Film Line Layouts For Improved Surface Treating Performance

In today’s race to produce film faster, thinner and with lower tension, reliable surface treatment is critical for success. There are a number of different philosophies employed when setting up a blown film line. Variables such as budget, available space, and specific application needs vary, but there are certain undeniable principles that can be used…

Read More