LEARN MORE All Press Releases

Filter by Application

Filter by Technology

Filter by Subcategory

Video Showcases Founding Principles & New Corporate Headquarters in the Words of Enercon Employees

Enercon Industries Corporation is pleased to release a new video which gives the industry an inside look at the company’s 50-year journey in becoming the leading induction cap sealing and...

Enercon Introduces New Patent Pending Quick Sleeve™ Tool for Replacing Silicone Sleeves on Corona Treater Ground Rolls

Enercon is pleased to announce the release of a new patent pending tool that saves film extruders time and money when replacing damaged silicone sleeves. The ingenious new design features...

Enercon Offers the Widest Range of Surface Treating Technologies at NPE

Get your chance to see the industries’ most comprehensive platform of PLASMA, FLAME & CORONA surface treating technologies in the FRONT ROW of NPE’s West Hall (Booth W6643). (Get your...

Comexi Selects Enercon Corona Treaters for Printers & Laminators for Center of Technology in Miami, Florida

Enercon Industries Corporation is pleased to announce that Comexi has selected Enercon Corona Treaters for their newest laminating and printing lines at their Center of Technology in Miami, Florida in...

Enercon Introduces New Corona Treater Electrode Assembly for Reduced Downtime

Enercon is pleased to announce a new Removable Cartridge with Quick Disconnect Electrodes that minimizes downtime when replacing corona treater electrodes and performing routine maintenance. The innovative design is available...

Enercon to Open New Corporate Headquarters

Release date: 9/7/2023 Enercon Industries Corporation is pleased to announce it is constructing a new facility to meet the demands of its growing customer base. The facility creates additional manufacturing...

Glenroy® Chooses Corona Treating Technology from Enercon for their Tandem Adhesive Laminator

Release date: 10/4/2023 Enercon Industries Corporation is pleased to announce that Glenroy® Inc. has selected Enercon Corona Treating Technology as they expand their capabilities for producing high barrier film laminations...

Nick Siler Named Enercon Industries Corporation Chief Operating Officer

Release date: 8/10/2023 Enercon Industries Corporation is pleased to announce that Nick Siler has joined Enercon Industries Corporation as Chief Operating Officer. “Adding Nick to our leadership team is a...

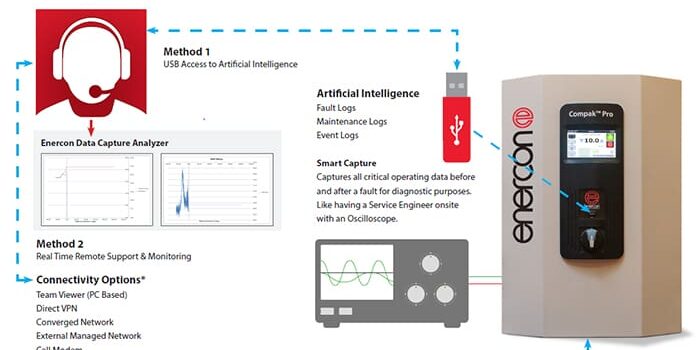

Enercon Tech & Support Helps Converters & Film Extruders Grow at Record Pace

Release date: 12/8/2021 Business is booming for Enercon’s customers in the converting and film extruding businesses. And, at no other time in history has the relationship between equipment users and...