Plasma and Flame Industrial Surface Treating Applications

SOLUTIONS Who uses plasma and flame treaters?

These technologies can be found in just about every industrial setting imaginable including: Automotive, Packaging, Window & Door, Medical, Wire & Cable, Assembly, Printing, Decorating, Folding carton and more.

The industrial applications spotlighted this page involve the spot treatment of dimensional objects and sheets prior to printing, painting, decorating, coating, coding, labeling, joining, assembling and bonding of surfaces.

PLASMA TREATING Applications

Get insights on plasma and flame for improving adhesive bonding.

Learn how surface treating is an integral part of the manufacturing of medical devices.

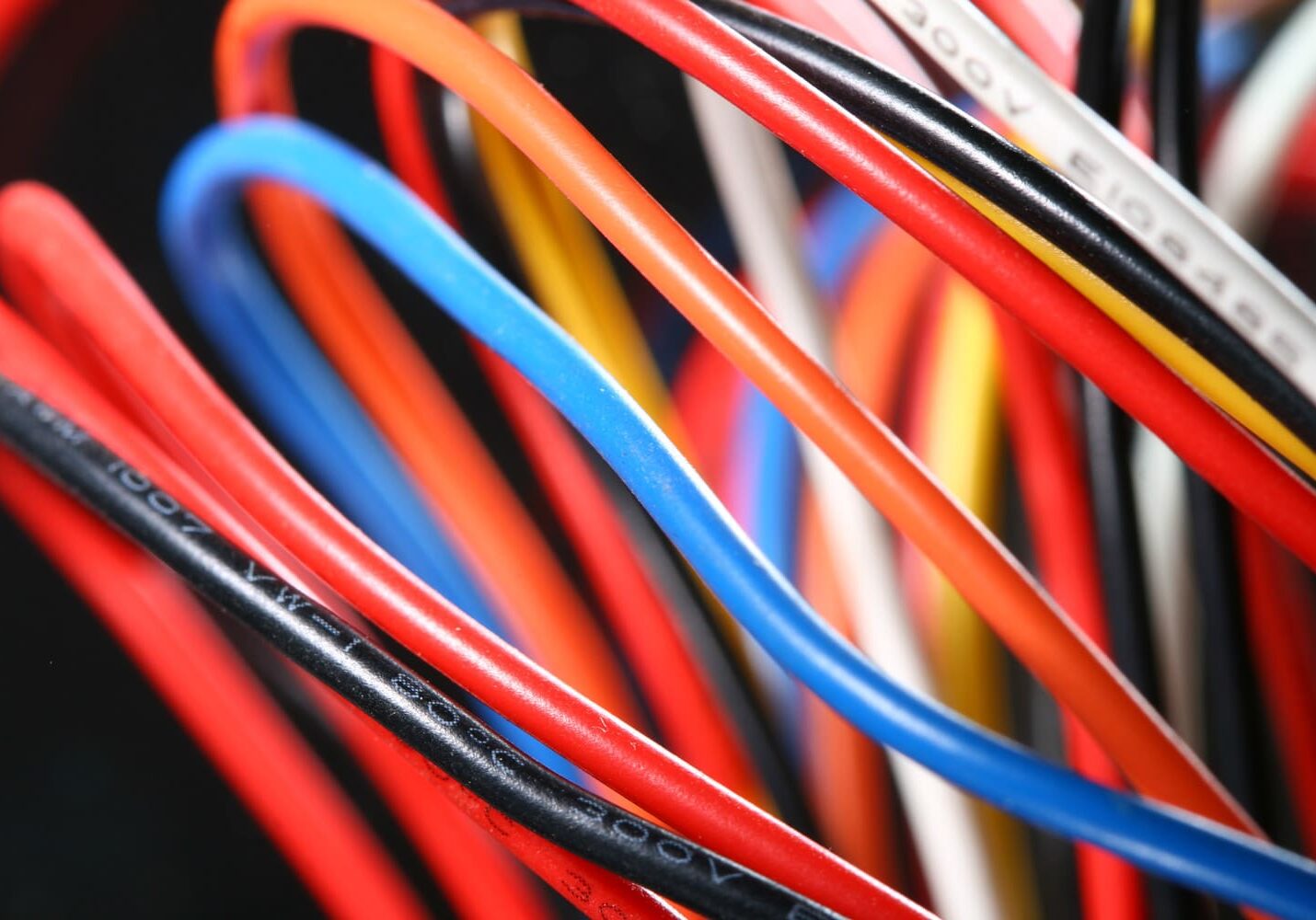

Learn how plasma is enabling ink jet printing on wires, cables & pipes.

GET IN TOUCH Get Free Expert Insights on Your Plasma Treating Products.

Our experts will help you troubleshoot existing issues and find solutions for your future projects. Call us at +1 262.255.6070.