Plasma and Flame Laboratory Surface Analysis

The best way to test the success of surface treatment is to immediately perform the next step in your process after treatment. If field evaluation is not possible, surface treating laboratory trials may be conducted with Enercon’s application engineers. They will test experiments with various plasma and flame treating technologies to determine which may be best for your application. Some of our customers request that we ship their samples back to them for additional testing. Others rely on the test results which can be achieved in the Enercon lab and are outlined below. It is important to note that while these diagnostics are indicators for the chances of adhesion success, no single result will positively guarantee the desired adhesion results.

Dyne Level

The most basic test is dyne level. Dynes are a unit of measurement that quantifies surface energy. This translates to surface wettability, one of the key requirements for successful adhesion. Your ink or adhesive supplier may recommend a desired dyne level as part of the recipe for achieving proper adhesion.

Dyne level testing is used extensively in the field as it is reasonably simple and inexpensive. Dyne pens are used frequently in production environments for quick verification of treated and untreated surfaces.

Contact Angle and Surface Polarity

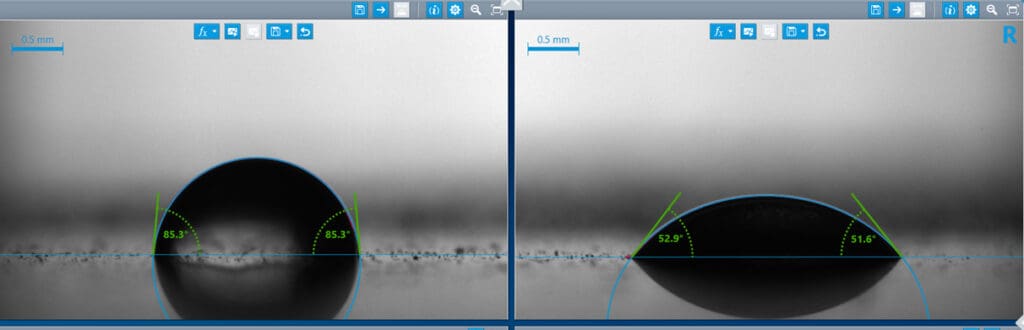

Contact angle testing also measures the degree of surface hydrophilicity (wettability). However, specialized equipment is required, making it more prominent in labs than in production environments. Enercon utilizes a Mobile Surface Analyzer which concurrently measures contact angle and free surface energy.

In this test, two parallel drops receive direct analysis of the contact angles and the derived results of the surface free energy. Contact angle measurements are more precise that dyne level testing. Meanwhile, surface free energy provides additional insights on potential adhesion success.

Friction/Peel Tests

If the object being tested has a sufficient flat area, a peel test may be employed. The test measures the coefficient of friction, peel strength, seal strength and tensile strength before and after treatment.

If you would like to schedule a laboratory trial for your next application please contact us.