New Atmospheric Plasma Surface Treating Technology for Wider and Uniform Treatment at High Speeds

A new technical paper recently presented at industry events details the benefits of a new Blown-Ion™ Plasma Technology featuring a MultiPort™ head design. The in-line plasma treater cleans, etches and functionalizes surfaces to improve bonding of adhesives, inks, paints, coatings and more. The design improves surface energy, wettability and bond strength at higher levels than conventional preparation methods, and is effective at higher line speeds offering less deviation in treatment results.

This new technology offers expanded capabilities for treating composites, plastics, glass and metals and is specifically designed to prepare surfaces prior to bonding by increasing surface energy and wettability.

In this technical paper data from three experiments are shared.

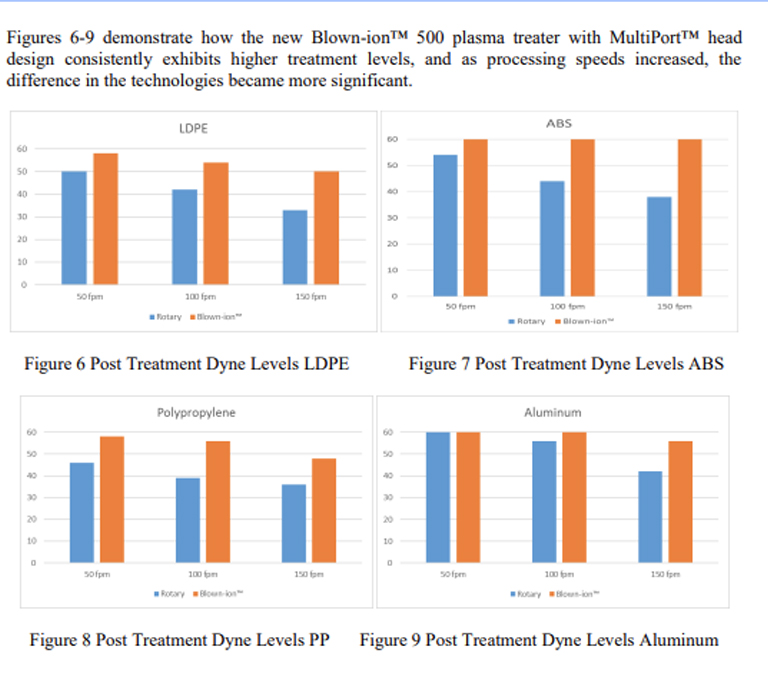

The first experiment demonstrates dyne level improvements on Low Density Polyethylene [LDPE], Polyethylene [PE], Acrylonitrile Butadiene Styrene [ABS], Polypropylene [PP] and Aluminum, at various process speeds. A Kruss Mobil Surface Analyzer [MSA] was then used to measure contact angle results showing a greater and more consistent improvement in contact angle for wettability when compared to rotary plasma technology.

The second and third experiments involve composite surfaces and combinations of surface preparation technologies including plasma treatment, peel ply, acetone, dry wipe and Scotch-Brite™ pads. Data shows that using Blown-ion™ plasma in conjunction with peel-ply yields a 16% increase in bond strength when compared to hand preparation and peel-ply methods.

Download the full technical paper to continue reading about new laboratory data which demonstrates how the industry can use this new technology to improve bonding in their operations.

Download This Informative Technical Paper Today