Analysis of New Flame Treatment Technology for Surface Modification and Adhesion Promotion

Abstract

Surface treatment technologies are commonly used to enhance the adhesion potential of base flexible packaging substrates for the application of performance adhesives, coatings and inks. The relationship between ribbon burner flame treatment technology and enhanced velocity (EV) port burner technology, and the degree of surface modification for adhesion promotion, is compared. Results showed that packages subjected to flame treatment prior to coating and printing performed significantly better, providing significant benefits. The subsequent measurement of dyne levels, peel adhesion and longevity tests following separate ribbon burner and drilled port flame surface treatments of various flexible packaging materials indicated definable differences between flame burner technologies and their effectiveness.

Introduction

Flame treatment was initially developed in the 1950s to improve the surface adhesion properties of polyolefin films. Flame treatment typically creates fixed levels of oxidized species on the surface of films, along with the formation of hydroxyl, carboxyl and carbonyl functionalities. Treatment (oxidation) depths vary by substrate, as does the generation of low molecular weight organic material at the surface. Flame plasmas have an electron density of approximately 108/cm and electron energies of 0.5 eV (electron volts). Surface exposure to flame treatment directly modifies electron distributions and densities of polyolefin molecules, resulting in polarization at the polymer surface up to several nanometers.

The purpose of this work is to provide an examination focused on flame burner technologies. This paper begins with an overview of existing burner technologies, followed by an examination of enhanced velocity (EV) port burner technology. We then present an experimental review of ribbon and EV port burner performance relative to surface tension, wettability and overall treatment effectiveness. By comparing these performance characteristics, the most effective burner technology can be identified.

Background & Development Effort

The design of existing flame treatment burner technologies has heretofore been driven primarily by the evolution of BOPP film production, paper/paperboard production and web coating technologies. BOPP processing speeds of 450 – 500 mpm are now common as are coating speeds of 600-800 mpm, and film widths can range up to 10 meters.

The improving performance of BOPP co-extrusions, PE, PET, polyamides and cavitated films has also required improvements in flame treatment performance. Flame system design impacts included better control of flame temperature and air gap at the burner, an increase in thermal output, burner cooling, better specific power (W/cm²) control, boundary layer penetration, flame stability, flame size and substrate dwell time within the flame. The predominant burner design being used in industrial applications are ribbon-type burners. They are designed for high heat release firing and are specified where a continuous flame is essential. They utilize .015-

.020 stainless steel “ribbons” and “flats” for flame retention and uniform heat distribution. Modification of the respective orientation, widths and depths of the ribbons and flats allows for changes in burner capacities, flame geometries and sizes. The burner bodies are typically constructed of joined cast iron segments and are water- cooled with either internal or external channels to prevent burner deflection due to thermal expansion. Control of ribbon burner energy output is primarily achieved by managing the air/gas mix, system air pressure and the burner design.

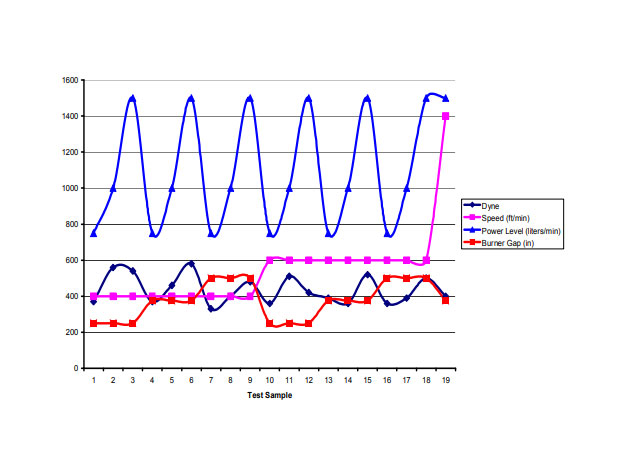

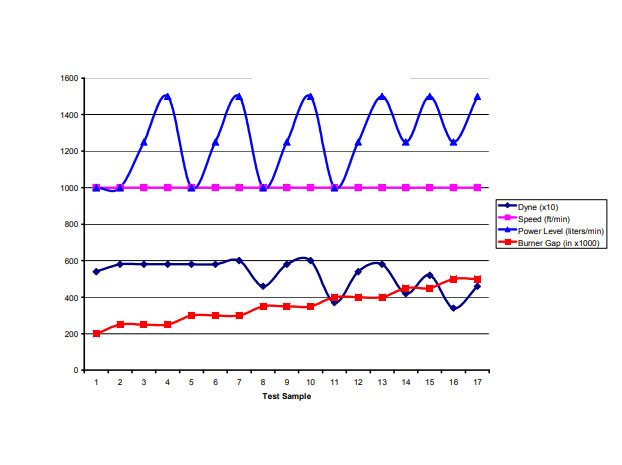

During our early efforts of evaluating ribbon and EV burner designs for use with new commercial-scale flame treatment technology it was logically observed that magnitude and longevity of treatment varied considerably as operating parameters were varied. Of particular note was the observation that in holding treatment speed of BOPP constant under varying power levels, surface energy levels as measured by dynes/cm can remain somewhat static under an increasing gap between the impinging flame and the BOPP substrate. Upon achieving a 40% increase in gap distance, dyne level decreased by an average of 10% and progressively decreased with increasing gap distance. Moreover, the decrease in surface energy was marginally affected with a 12.5% increase in power level (see Figure 1). The same primary influence of gap on dyne level was confirmed with broad trial fluctuations in the power level and speed variables (see Figure 2). In this series of tests, it is important to note that a 50% increase in speed reduced dyne level an average of 10%.

This observation led to the hypothesis that development of a burner design consisting of a high velocity flame may deliver more surface treatment period unit of time and effectively lead to treatment productivity improvements. The potential to increase the gap distance between the burner and the substrate to be treated was also considered a possible outcome of development.

The primary development objectives of EV burner technology included:

- Increased thermal efficiency

- Greater heat transfer (luminous flame radiative cooling effect)

- Increase treatment rate

- Low burner deflection/greater gap stability through improved internal recirculative cooling

- Port inserts which can be easily removed/cleaned in the field

There are two velocities which compose the shape and treatment efficacy of a burner flame – the velocity of the air/gas flow to/from the burner, and the formed velocity of the flame itself. The focus of control of these velocities was within the design of the combustion system and burner ports.

Experimental

Performance statistics of the developed 60” wide 500,000 BTU/hr./in. water-cooled EV burner with a proprietary pilot/main flame port design were compared to a 60” wide 500,000 BTU/hr./in. water-cooled ribbon burner comprising of 15 ribbons and 6 flats. The EV burner design was constructed with an aluminum body, and the ribbon burner constructed of cast iron. The stoichiometric ratio was maintained at approximately 9.55:1 for the air/methane flame analysis within a relatively dry air environment of approximately 21% O2 and 79% N2. The backing chill roll temperature was maintained at 40°C.

Extensive trials were initially undertaken with OPP film and LDPE-coated paperboard substrates in order to optimize the impingement of the luminous flame cones for each burner type relative to the substrate surface under three experimental flame power settings. The optimized gap for the proprietary EV burner was determined to be .425”, with the ribbon burner optimized at .187”. The OPP film and coated paperboard were transported through the flame at speeds of 600, 1000, 1200 and 1400 fpm. Thermal energy input into the film and paperboard are considered to be a function of flame power, dwell time, flame treater station design and the distance between the burner surface and the substrate.

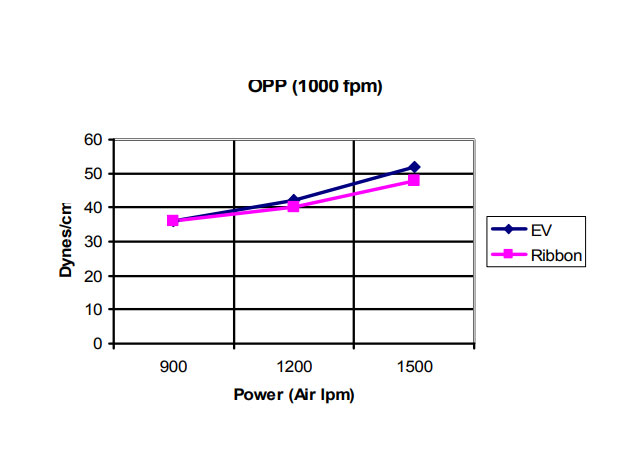

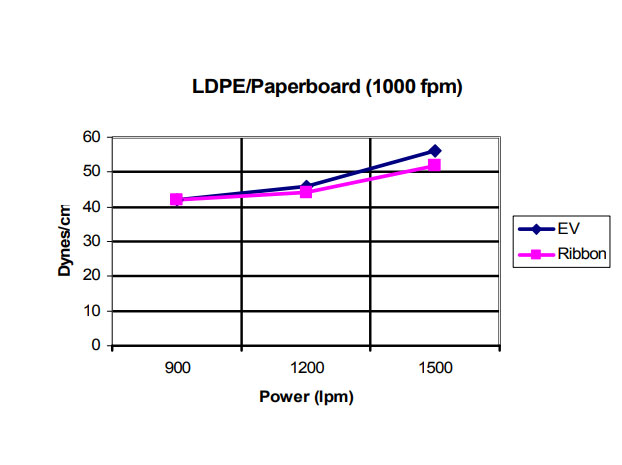

The OPP film was flame treated at specific variations in power levels and speed, and then ASTM standard wetting test were performed. While the ASTM wetting test is not an accurate measure of wettability or adhesion, it is the most widely used test for evaluating the wettability of modified surfaces. The untreated OPP film had an ASTM wetting test value of 32 dynes/cm. The typical standard deviation for the ASTM wetting test is ± 1-2 dynes/cm. As can be seen in Figure 3 below, the dyne level of the OPP using the EV burner exceeded the

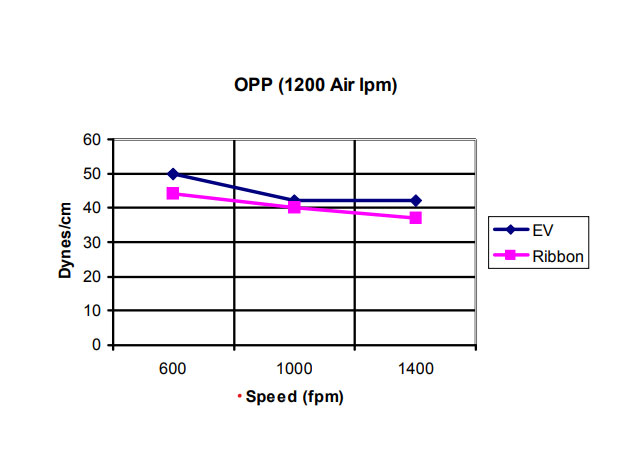

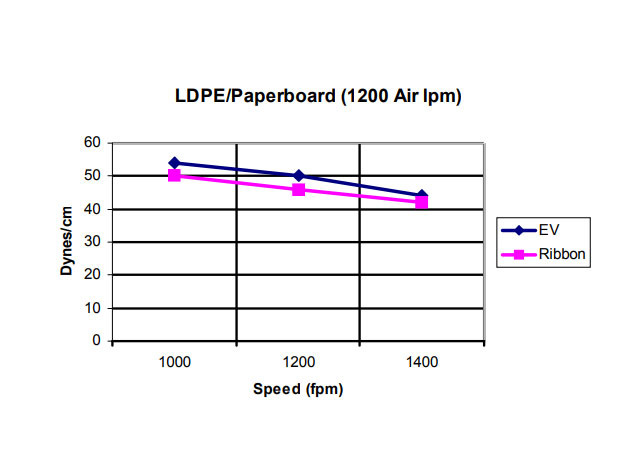

ribbon burner dyne level by an average of 4.6% at a fixed speed of 1000 fpm. When the power level was held constant, the EV burner exceeded the ribbon burner dyne level by an average of 9.7% (see Figure 4).

The same analysis was conducted with the LDPE-coated paperboard. The untreated paperboard had an ASTM wetting test value of 34 dynes/cm. The dyne level of the LDPE-coated paperboard using the EV burner exceeded the ribbon burner dyne level by an average of 4.3% at a fixed speed of 1000 fpm as seen in Figure 5. When the power level was held constant, the EV burner exceeded the ribbon burner dyne level by an average of 7.2%

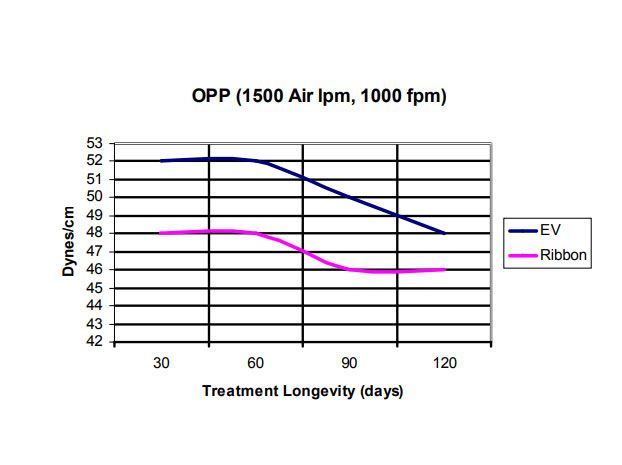

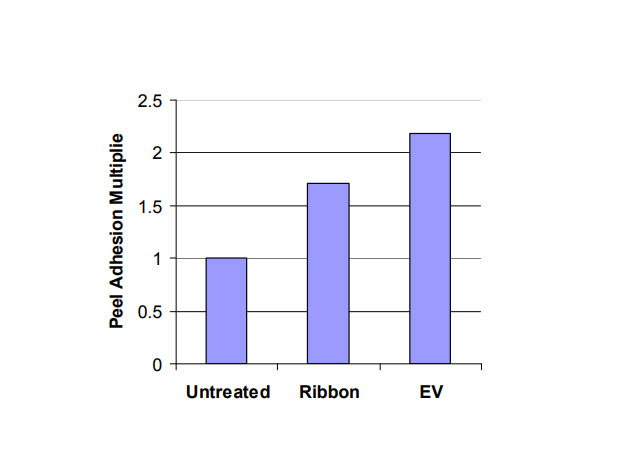

Treatment longevity comparisons between the EV burner and ribbon burner technologies yielded little variation relative to their respective treatment degradation rates over a 120 day period. A 3% differential in degradation rate of the chemical modification on the polymer surface was noted (Figure 7). In addition, peel adhesion tests on OPP film were conducted under ASTM D3330 requirements. In this test, a specified pressure-sensitive tape (3M No. 851) is applied to the treated surface using a weighted roller. The peel strength was measured with a

tensiometer under the treatment conditions of 1500 lpm and 1000 fpm, and under the aforementioned optimized gap for each burner. Specifying the untreated OPP as having an adhesion multiplier of 1, the results indicated that peel adhesion using the EV burner exceeded the peel adhesion of the ribbon burner by a multiplier difference of .48 or 28% (Figure 8).

Conclusions

The surface energy of the test substrates of OPP film and LDPE-coated paperboard was increased by an average of 4.6% and 4.3%, respectively at a fixed speed using the EV burner when compared to the ribbon burner.

Moreover, the surface energy of these same substrates were increased by an average of 9.7% and 7.2%, respectively, over ribbon burner results with the EV burner when power level was held constant. There was no discernable difference in treatment longevity on either substrate between the burner types. However, peel adhesion tests on OPP film employing each burner at the same trial speed and power level conditions indicated the potential for significantly improved peel adhesion using the EV burner design. Also, extensive preliminary testing indicated that an increase of .238” in gap distance could be achieved between the top face of the EV burner design relative to the production scale ribbon burner used in this evaluation.

References

- Jones, H.R.N. (Howard Richard Neil), “The Application of Combustion Principles to Domestic Gas Burner Design”, E. & F.N. Spon Ltd.(1989).

- Mittal, K.L., and Pizzi, A., “Adhesion Promotion Techniques: Technological Applications”, Marcel Dekker (1999).

- Brewis, D.M. and Mathieson, I., “Adhesion and Bonding to Polyolefins”, Rapra (2002).