Blame the Corona Treater

The Truth about Dyne Levels, Watt Density & Adhesion When inks, coatings, adhesives and laminations don’t bond with substrates, converters are quick to blame the corona treater. And why shouldn’t they? Corona treaters are responsible for adhesion, right? Well, not exactly. This article looks into the relationship between the corona treater and adhesion. We’ll dive…

Read MoreBest Practices & Developments in Solventless Laminating

Printers and converters who integrate solventless laminating enjoy a competitive advantage by offering their customers a single source for flexible packaging. Thanks to recent advancements in laminating process technology, adhesive chemistry and equipment design, implementing a solventless laminating operation has never been easier. This paper details the importance of operators understanding the principles and variables…

Read More5 Keys to Optimizing Your Surface Treating Operations

Applications for surface treating continue to grow at a remarkable rate. From the ever-expanding flexible packaging market to emerging technology sectors such as solar and batteries for electric vehicles, corona, flame and plasma technologies are being used to promote adhesion on all types of films and foils. Whether you are an industry veteran or new…

Read MoreCan you use Watt Density to Predict Dyne Levels?

The ultimate goal of any surface treatment system is to increase surface tension measured in dynes which then increases the wettability and adhesion characteristics of the surface. This allows you to add value to the substrate through printing, laminating, coating etc.. Corona treating systems achieve this by applying a given level of power over a…

Read MoreTips for maximizing the life of your ceramic electrodes

Ceramic electrodes are used extensively in the converting industry for creating corona to improve the surface energy of conductive and nonconductive films and foils. These rugged electrodes are designed to survive the cauldron of heat, ozone and electrical discharge created by the corona treating process. To ensure the electrodes continue to perform as designed operations…

Read MoreImproving UV Coating Results with Corona & Plasma Surface Preparation

UV coatings are a great choice for high value applications where scratch resistance and surface performance are essential. While traditional UV lamps are still used, the advancement of LED curing technology has improved operational efficiencies for numerous applications. As seen in the UV+EB Technology Magazine, this article reviews the importance of properly preparing surfaces for…

Read MoreSurface Treating Insights for Substrates Used in Lithium-ion Battery Production

The global demand for high performing Lithium-ion and Electric Vehicle batteries is on the rise. Many of the foil and polymer film substrates used for these applications require surface treatment to enable proper coating adhesion and battery performance. Many innovators in this market rely on Enercon’s surface treating laboratory as the proving ground for optimizing…

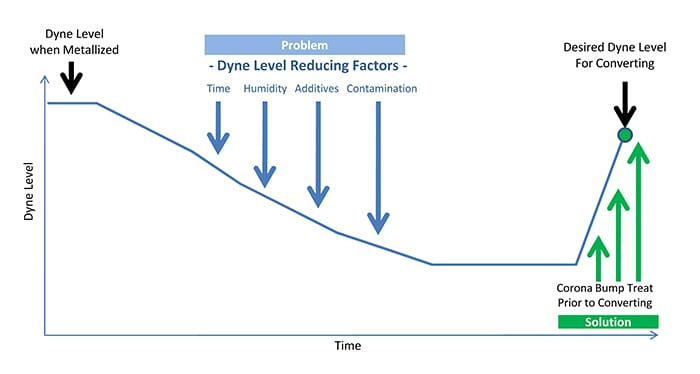

Read MoreHow Bump Corona Treating Improves Laminating, Coating & Printing

Whose responsibility is it to make sure a film is ready to be converted? Film supplier or Converter? Depending on what part of the world you are in this question can spark an inspired debate. Both the film supplier and the converter are in business to make money. When printing, coating & laminating applications go…

Read MorePattern Corona Treating Offers Flexibility for Pouches & Bags

Corona treatment is widely used by flexographic printers to control surface energy for successful ink adhesion. In most cases, treating the entire width of the web is required. However applications requiring selective treatment are becoming more popular. Printing Stand-up PouchesStand-up pouches are made up of non-porous barrier films which require treatment prior to printing. However, corona…

Read MoreMaintain or reinvest in a corona treater? What’s a converter to do?

Can you afford to maintain your old surface treater? Your organization has probably seen its share of downsizing. And your resources are spread about as thin as can be. As you look to do more with less it can be a difficult time to justify an investment in new equipment. But how much is that…

Read More