Why All Films Do Not Treat the Same And What You Need to Know When You Get Unexpected Treatment Results

The goal of a corona treater is to increase a film’s ability to bond with an ink, coating or lamination. But did you know that different types of film respond very differently to the same levels of corona treatment? Some films, like PS, respond very well to treatment at low power levels, while others, like polypropylene,…

Read MoreEquistar leverages the benefits of atmospheric plasma surface treating

Equistar Chemicals LP, is one of the world’s largest producers of ethylene, propylene, and polyethylene resins. Its facilities have a combined annual capacity to produce more than 11 billion lb of ethylene and more than 5 billion lb of polyethylene, along with other specialty products such as ethyl vinyl acetate. So it’s not surprising Equistar’s…

Read MoreStop High Voltage Arcs Before They Cause Downtime

In corona treating, a high voltage arc occurs when the intended path of electrical current is disrupted because it finds an easier path to ground. Over 80% of the time, the location of the high voltage arc is in the area of the electrode and ground roll where corona is created. This webinar explains how…

Read MoreHow to Extend the Life of Your Ceramic Electrodes

Did you know that some Enercon customers have never had a failed ceramic electrode? If you’re like most converters you may find that hard to believe. What impact would it have on your business if you could reduce occurrences of failed electrodes? Reasons for electrode failures include overheating, overpowering and physical shock. Overheating is the…

Read MoreWeb Handling Best Practices for Surface Treating & Converting

Poor web handling creates trouble for your corona treater operations. In fact, poor web handling is often a hidden root cause of suspected treatment issues. The good news is you can avoid these problems. The key is accurately defining your application so your corona treater supplier & OEM can employ the web handling techniques needed…

Read MoreCorona Treating Maintenance Best Practices

This informative webinar will provide you with the industry’s best practices to keep your corona treater in top running condition. Learn what to look for and how to remedy common problems that cause downtime: From electrodes to rolls, from power supplies to exhaust system, this webinar covers it all.

Read MoreSolventless Laminating Best Practices

Printers and converters who integrate solventless laminating enjoy a competitive advantage by offering their customers a single source for flexible packaging. Thanks to recent advancements in laminating process technology, adhesive chemistry and equipment design, implementing a solventless laminating operation has never been easier. However, it’s important that operators understand the basic principles and variables of…

Read MoreFirst Responders Corona Treater Training

Every operation needs one: Your go-to person when your corona treater needs attention. We call them corona treater first responders and we’ve created this webinar just for them. We’ll dive into four situations that can occur with corona treaters and how to systematically approach each situation to reach a swift resolution. This new webinar will…

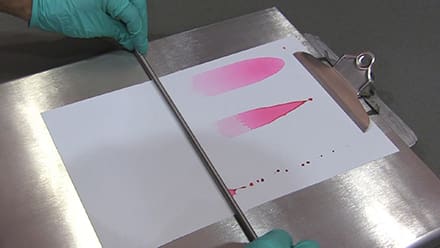

Read MoreTruth or Dyne? How to Properly Conduct Dyne Tests & What Your Results Really Mean

Corona treaters are used to increase a film’s surface energy to enable wettability & promote the adhesion of inks, coatings and adhesives. This change in surface energy is most commonly measured in dynes. And that’s where problems for extruders and converters begin. Poorly executed dyne tests produce unreliable results and assumptions about dyne levels lead…

Read MoreNext Generation Corona Treaters: How Smart New Features Will Make Your Operation More Profitable

Start/Stop. Power Up/Down. Who could ask for more? Well, you should; and now Enercon is making it possible. To compete at a high level, you need the right technology to support your operation. We’re talking about innovative systems that do the thinking for you. Enercon’s design engineering team has developed leading edge technology to take…

Read More