Troubleshooting Solventless Laminating Applications

In this new on-demand webinar, learn how to spot root causes of solventless laminating issues and how to resolve common challenges that arise when solventless lamination fails. Industry experts from Nordmeccanica, COIM Group, and Enercon reassemble to provide tips on: Filling out the form to the right will give you instant access to the full…

Read MoreOptimizing Extrusion Coating Lines for Bio Resin Adhesion & Performance

Demand for sustainable packaging is forcing extrusion coating operations to add bio resin capabilities to their existing lines. While the principles of the extrusion coating process remain the same, the application variables presented by bio resins creates challenges in achieving proper adhesion and meeting production goals. In this new webinar, the surface treating experts at…

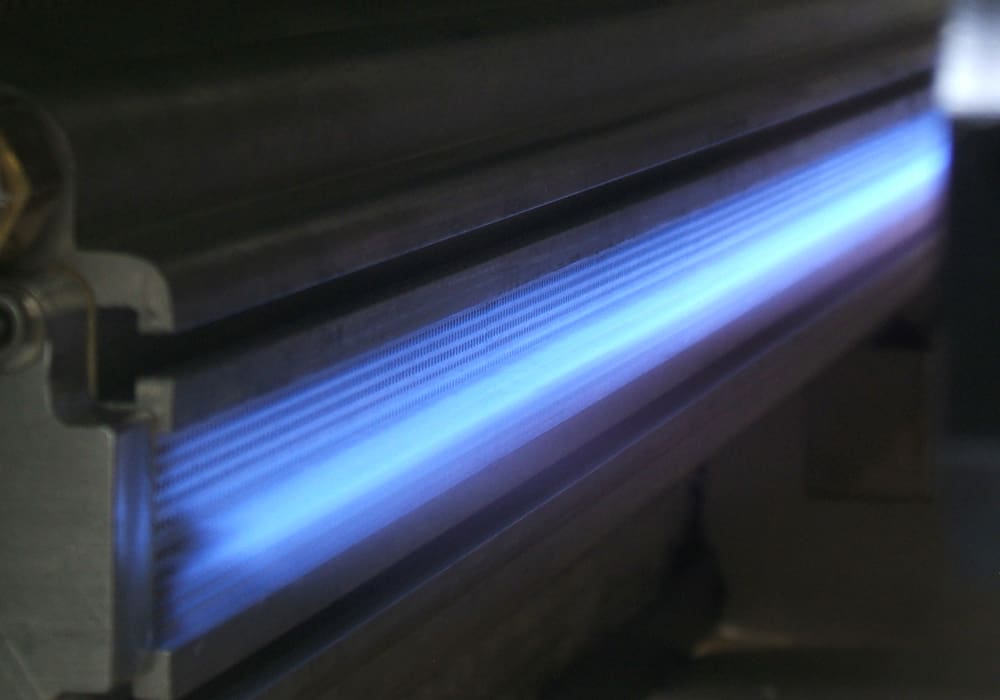

Read MoreHow Flame Control Systems Optimize Treatment

Flame is the world’s original surface treater and is commonly used on extrusion coating lines, paperboard processing and foil cleaning applications. If you haven’t considered a flame treater in some time you will be surprised at today’s advanced combustion control options and new high velocity burners that deliver effective and repeatable treatment. Managing the chemistry…

Read MoreImprove Print Quality & Productivity by Controlling Substrate Surface Energy

Poor ink adhesion affects print quality, creates downtime, and leads to lost customers. In many cases, the cause is rooted in complications from the substrate surface. The good news is that surface variables can be eliminated with the proper use of a corona treater. A common misunderstanding is that pretreated films eliminate the need for…

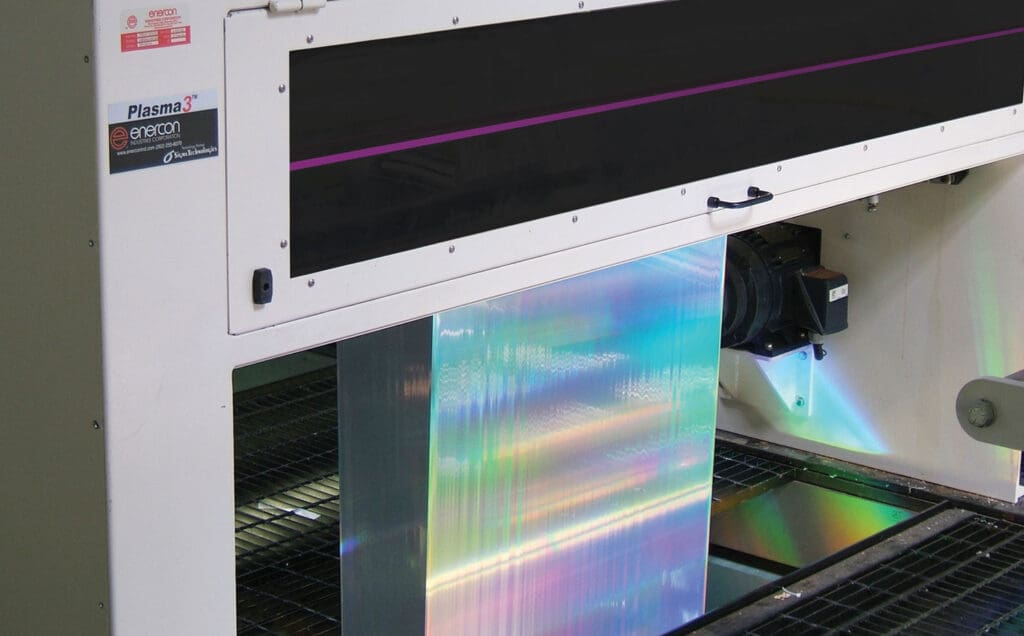

Read MoreMetallized Film Adhesion: Processing & Converting with Surface Treatment

Metallized film presents adhesion challenges to both film suppliers and converters. Today, new developments in surface treatment are creating competitive advantages by extending surface energy stability on metallized film. What metallized film converters should know Both the metallized film supplier and converter are at the mercy of the physics involved with dyne levels. Dyne level…

Read MoreImprove Lamination Adhesion with Surface Treating

For many industrial applications, the use of a single ply of a material does not provide all of the critical properties required for the optimal performance of a product. In these cases, a composite of two or more layers of material can provide this required performance. A common method of creating such a composite is…

Read MoreImprove Ink Printing Adhesion with Surface Treating

The task of optimizing printing adhesion can be difficult, primarily because of the many process variables which require control. The most critical of these parameters are 1) ink chemistry, 2) substrate quality, 3) surface treatment, and 4) ink transfer method. There are six major printing/decorating processes, each distinguished by the method in which ink and…

Read MoreCompak 2000 flip top power supply provides fast and easy diagnostic troubleshooting.

The most recent improvement to Enercon’s line of power supplies is the new Compak™ 2000 Flip-Top style power supply. At first glance you’ll notice a change in the size of the cabinet. You might also notice a minor change in the diagnostic display symbols and the description of the diagnostics offered. The diagnostics are intended to provide…

Read MoreGetting Started with Corona Surface Treatment

This free eBook shares expert insights from Surface Treating Experts. Discover how Converters & Extruders use Corona Treating to Improve Adhesion Corona treating improves a film’s receptiveness to inks, coatings, and adhesives. In this informative eBook, you’ll find insights on how corona treating works, application examples and considerations when specifying corona treaters. See what Enercon…

Read MoreWhy All Films Do Not Treat the Same And What You Need to Know When You Get Unexpected Treatment Results

The goal of a corona treater is to increase a film’s ability to bond with an ink, coating or lamination. But did you know that different types of film respond very differently to the same levels of corona treatment? Some films, like PS, respond very well to treatment at low power levels, while others, like polypropylene,…

Read More