Blame the Corona Treater: The Truth About Watt Density, Dyne Level & Adhesion

When inks, coatings, adhesives and laminates don’t bond with substrates, converters are quick to blame the corona treater. And why shouldn’t they? Corona treaters are responsible for adhesion, right? Well, not exactly. In this insightful webinar, industry veterans Tom Gilbertson and Todd Krupa dive deep into the relationships between watt density, dyne levels and adhesion.…

Read MoreBlame the Corona Treater

The Truth about Dyne Levels, Watt Density & Adhesion When inks, coatings, adhesives and laminations don’t bond with substrates, converters are quick to blame the corona treater. And why shouldn’t they? Corona treaters are responsible for adhesion, right? Well, not exactly. This article looks into the relationship between the corona treater and adhesion. We’ll dive…

Read MoreCan you use Watt Density to Predict Dyne Levels?

The ultimate goal of any surface treatment system is to increase surface tension measured in dynes which then increases the wettability and adhesion characteristics of the surface. This allows you to add value to the substrate through printing, laminating, coating etc.. Corona treating systems achieve this by applying a given level of power over a…

Read MoreWhy All Films Do Not Treat the Same

The Signature Relationship Between Your Film and Corona Treaters How well do you understand the relationship between your films and your corona treater? A treatment level of 2.0 watt density yields very different results on PET compared to Polypropylene. And, a nominal change in watt density can produce unexpected results. This paper looks at the…

Read MoreProper Dyne Testing Methods: Buddy, Can You Spare a Dyne?

Dyne Tests Only Work When You Do Them Right Dynes are used to measure changes in a film’s surface energy. But poorly executed dyne tests produce unreliable results. And false assumptions about dyne levels, adhesion and corona treating leads to major problems. This insightful technical paper reviews best practices for dyne pen, cotton swab, and…

Read MoreTAPPI Mayer Rod Drawdown Dyne Testing

The Mayer Rod Drawdown Method is an industry standard under TAPPI Test Method T 552: Determination of Wetting Tension of Polyolefin Films and Coated Surfaces via the Mayer Rod Technique. How to apply:A substrate sample, usually measuring 8-1/2 x 11 inches, is clamped to a clipboard. At the top of the sample, a single drop…

Read MoreASTM Cotton Swab Dyne Testing

The Cotton Swab Method is recognized as an industry standard under ASTM D2578-17, Standard Test Method for Wetting Tension of Polyethylene and Polypropylene Films. Dyne solutions of various concentrations are placed on the substrate until a solution is found that wets out properly. How to apply:Drops of a dyne test solution are placed on the tip…

Read MoreTroubleshooting Dyne Levels for Cast and Blown Film Lines

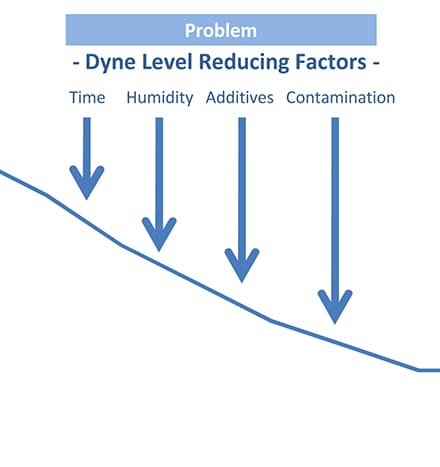

“That film you sent me was supposed to be 42 dynes! I can’t convert this stuff and I’ve got orders due!!!” exclaims the exasperated converter. “Hold on a minute, I’m sure we shipped you film that was 42 dynes, let me look into this,” contends the film producer. When dyne levels are insufficient, it’s a…

Read MoreSolving Metallized Film Converting Adhesion Issues

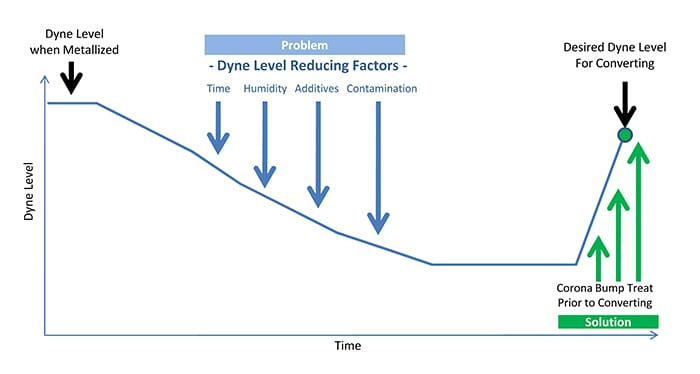

Most application questions involving the converting of metallized films concern the dyne level required to convert. It is extremely important for both the film manufacturer and the converter to recognize that achieving a specific dyne level does not guarantee printing, coating or laminating adhesion. Most converters will conduct a dyne test on metallized film prior…

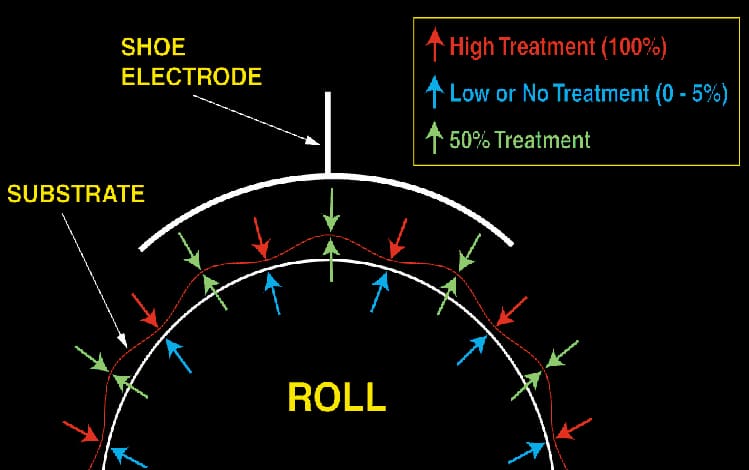

Read MorePrevent Backside Treatment

The bad news is that backside treatment mitigates the effects of surface treating. In some cases, it results in under treatment of substrates. It can also raise the energy of the backside surface creating processing problems. In bag making and seal applications, backside treatment can alter the substrate’s co-efficient of friction. This will ultimately cause…

Read More