Powerful & Reliable Corona Treatment for Cast Film Lines

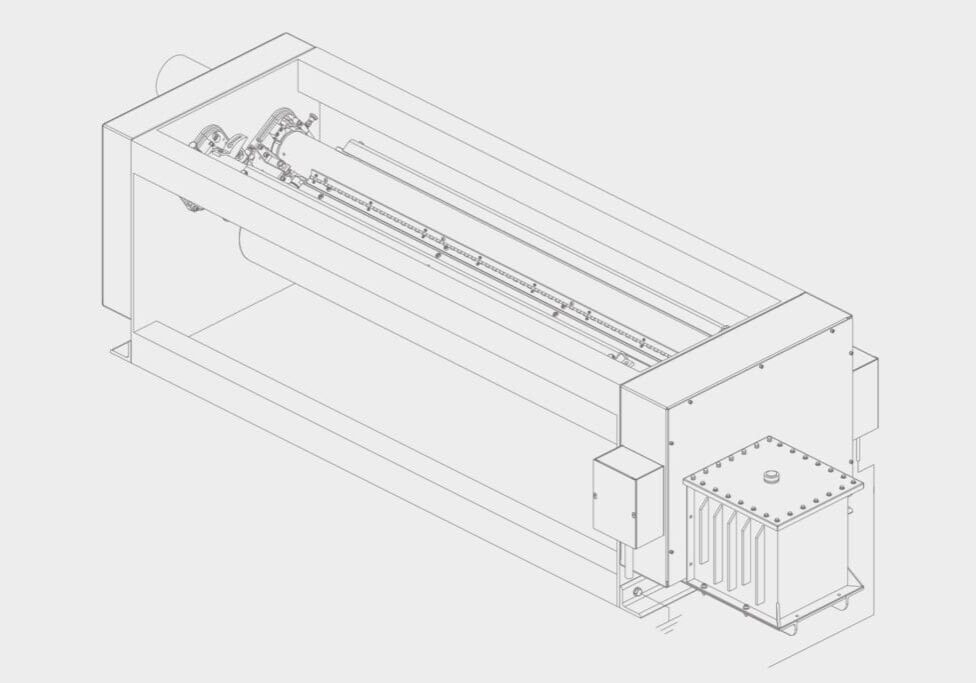

Corona Stations, Electrode Assemblies & Power Supplies

Enercon offers corona treating solutions specifically designed for cast film lines producing BOPP, OPP, BOPET & BOPA. Our robust electrode assembly design features smart pneumatics to prevent damage from web breaks. And intuitive touch screen power supplies make this the simplest corona treater you’ll ever operate.

Electrode Assemblies

- Easy-set Fine & Gross Electrode Air Gap Adjustment

- Robust & powerful stainless steel tube electrodes

- Floating electrode design for thermal stability

- Exhaust system for cooling & ozone removal

Smart Pneumatics

Enercon’s innovative Smart Pneumatics pivot electrode assemblies out of the way to avoid damage from web breaks at high speeds. The system maintains low pressure to keep the electrode in the operating position. When pressure against the assembly is detected the smart pneumatics apply force to pivot the assembly away from the web. Force is also applied to the electrode assembly when returning to the treat position to ensure proper positioning.

Integrated Artificial Intelligence

Remarkable new support features include on board troubleshooting tips, custom maintenance reminders and explicit real time fault monitoring. In addition to logging and time stamping any faults, its integrated artificial intelligence automatically recognizes when a fault takes place and captures a detailed snapshot of operating data. This is the equivalent of having a service technician monitoring the system with advanced diagnostic tools.

A USB port allows users to download this data and share with Enercon Service Engineers for quick resolution of any issues. Users can also use the USB to capture maintenance and event logs as well as update software in the field.

Enercon systems are designed to operate in a maximum ambient temperature of 40°C (104°F) @ 80% relative humidity, non-condensing.

KEY FEATURES For Successful Ultrawide Film Treatment

-

Consistent & Reliable Corona Treatment

-

Advanced Power Supply Design & Control

-

Robust Electrodes with Smart Pneumatics

-

Thermal Cooling & Ozone Removal Exhaust System

-

Global Application & Technical Support

CORONA TREATING POWER SUPPLIES

Reliable industry workhorse for basic applications

Proven Reliability with Advanced Features

OPTIONAL EQUIPMENT Which may be recommended or specified:

-

Idler Rolls

-

Network Communication

-

Nip Rolls

-

Ozone Decomposer

-

Quick Disconnect Electrode Cartridge

-

Spare Electrodes

-

Spare Parts Kit

-

Spare Ground Rolls

-

Start-up Assistance

-

Station Guarding