PLASMA TREATING Featured Customer Application Stories

LEARN MORE All Application Articles

Filter by Application

Filter by Technology

Filter by Material

Filter by Subcategory

Plasma Replaces Propane Torch to Improve Print Adhesion on PE Pipes

As one of the largest manufacturers and distributors of piping in Canada, CB Supplies is continuously looking for new technologies to improve efficiencies and support environmental conservation. Their recent investment...

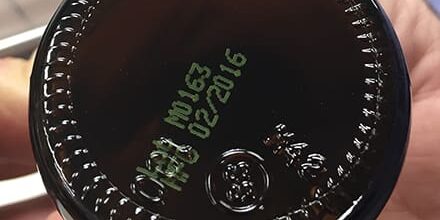

Enercon Plasma Treater is a Game Changer for Biovation Labs’ FDA – Approved Packaging

Biovation Labs is an NSF 455-2 registered facility, providing their high-quality formulation, blending, encapsulation, tableting, and packaging. As a certified cGMP (Current Good Manufacturing Practices) facility, Biovation Labs takes pride in...

Plasma Treating Tubes Ensures Ink Adhesion and Increases Production Efficiency

Plastube is a Canadian manufacturer of innovative plastic tubes for the beauty, healthcare, food and pharmaceutical industries. The company produces and prints polyethylene tubes, tubes with an inner foil and...

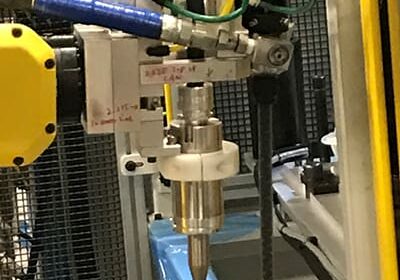

Solving Potting and Assembly Adhesion Challenges with Custom Solutions

Mertek Solutions, Inc. (Sanford, NC) designs and builds custom machinery for automated manufacturing in a wide variety of industries including automotive, medical, packaging, assembly, consumer goods, appliances and plastics. The...

Improve Label Adhesion on Bottles – Flame & Plasma Treaters

When packagers are faced with label adhesion challenges, flame and plasma surface treaters are often used to increase bond strength. Label adhesion problems on bottles occur because many of the...

Plasma and Flame Surface Treating Enable Automotive Adhesive Bonds

TA Systems of Rochester Hills, Michigan, specializes in engineering custom automation solutions for the automotive industry. Their customers rely on them to integrate multiple technologies and processes into efficient manufacturing...

Flame Treater Cures Downtime, Eliminates Poor Ink Adhesion

Centor (Millersburg,OH) is one of the leading suppliers of caps and bottles used for prescription medications. They manufacture containers in all shapes and sizes for pills and liquids you would...

Folding Carton Manufacturer Eliminates Solvent Adhesive

Folding carton manufacturer Evergo Packaging prides itself on being environmentally conscious and ahead of the curve when it comes to its printing and packaging technologies. The company is certified by the Forest...