How to Set Your Wide Web Corona Treater’s Air Gap

For more information on how to adjust your air gap please consult your Enercon manual for a detailed procedure or contact Enercon’s service team. You may also request a complimentary Enercon gap gauge as seen in the video.

Read MoreMeasuring Surface Energy On Non-Woven Substrates

There is no easy way to determine changes in surface energy on non-woven and woven substrates and we know of no official standards such as an ASTM method but there is a procedure. There are several methods to characterize the surface energy of nonwovens fibers. Of these, contact angle is the most readily applied. One…

Read MoreRecommended Surface Energy & Treatment Ranges for Printing & Coating Polymer Surfaces

We’re often asked what dyne level do I need to print on a particular type of film. Its a complex question that includes many variables beyond the material type and method of printing or coating. We can however provide general guidelines that you can use to start your own evaluations. The tables below list general…

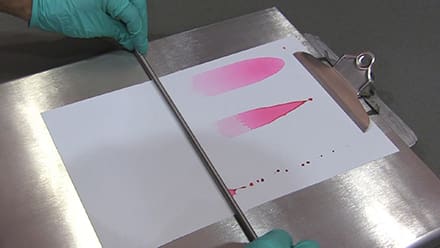

Read MoreUsing Dyne Solutions and Dyne Pens to Measure Surface Energy On Non-Porous Substrates

Non-porous substrates, such as polyethylene, polypropylene and foils, need to have their surface energies altered in order for the proper flexographic ink adhesion to occur. An old general rule of thumb is that the substrate should have a dyne level (surface-energy measurement) of at least 10 dynes higher than the surface energy of the ink…

Read MoreBest Practices for Extrusion Coating Surface Treating

Watch this new webinar where surface treating experts take the guesswork out of determining which surface treating technologies will provide you with the best results. You’ll get insights on how to leverage corona, flame and ozone technologies to maximize your extrusion coating bonding results and efficiencies. Topics Include: Innovative People Ensuring Your Treating Success. Enercon is…

Read MoreWhy All Films Do Not Treat the Same And What You Need to Know When You Get Unexpected Treatment Results

The goal of a corona treater is to increase a film’s ability to bond with an ink, coating or lamination. But did you know that different types of film respond very differently to the same levels of corona treatment? Some films, like PS, respond very well to treatment at low power levels, while others, like polypropylene,…

Read MoreEquistar leverages the benefits of atmospheric plasma surface treating

Equistar Chemicals LP, is one of the world’s largest producers of ethylene, propylene, and polyethylene resins. Its facilities have a combined annual capacity to produce more than 11 billion lb of ethylene and more than 5 billion lb of polyethylene, along with other specialty products such as ethyl vinyl acetate. So it’s not surprising Equistar’s…

Read MoreStop High Voltage Arcs Before They Cause Downtime

In corona treating, a high voltage arc occurs when the intended path of electrical current is disrupted because it finds an easier path to ground. Over 80% of the time, the location of the high voltage arc is in the area of the electrode and ground roll where corona is created. This webinar explains how…

Read MoreCorona Treating Maintenance Best Practices

This informative webinar will provide you with the industry’s best practices to keep your corona treater in top running condition. Learn what to look for and how to remedy common problems that cause downtime: From electrodes to rolls, from power supplies to exhaust system, this webinar covers it all.

Read MoreFirst Responders Corona Treater Training

Every operation needs one: Your go-to person when your corona treater needs attention. We call them corona treater first responders and we’ve created this webinar just for them. We’ll dive into four situations that can occur with corona treaters and how to systematically approach each situation to reach a swift resolution. This new webinar will…

Read More