Inspect, Detect & Reject Your Way to Increased Cap Seal Productivity

You’ve chosen an induction sealer to prevent leaks, provide tamper evidence and preserve product freshness. It’s a key component of your packaging strategy and your team should be well trained on both the induction sealing process and inspection & detection options that can increase your productivity. This webinar showcases technologies that ensure more containers are…

Read MoreHow New Cap Sealers Improve Productivity with Process Control Options

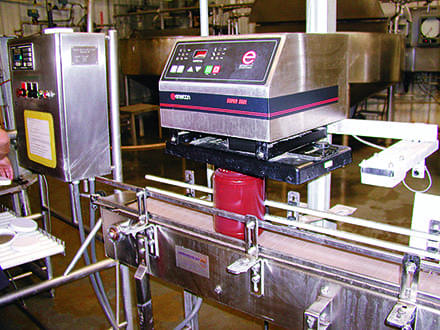

Enercon’s NEW Super Seal cap sealer is helping packagers achieve perfect hermetic seals with a new feature set that was previously available only on Enercon’s more advanced cap sealer models. Integrated options now include monitoring container movement through the sealer, detecting those caps without a foil liner, and rejecting faulty containers. Plus, the New Super…

Read MoreOptimize Your Caps, Liners & Capping for Induction Sealing

Get an in-depth perspective of the relationship between liners, caps, cappers & sealers. Discover the critical interactions for successful cap sealing when designing a package. Expert panel will offer their insights on the following topics: Manufacturers of liners, caps, cappers & sealers will discuss the critical elements of each of these components, and the importance…

Read MoreBoost Induction Cap Sealer Productivity & Reduce Rejects

Master Your Induction Cap Sealer’s Features & Options Learn how to control and monitor sealing energy, use inspection to improve quality control, and why electrically integrating your cap sealer is vital. Strategies will be shared to boost your productivity and reduce rejects. Innovative People Ensuring Your Sealing Success. Enercon is the world’s leading manufacturer of…

Read MoreTips for Sealing Liquids for Shipping with Amazon, FedEx & UPS

UPS, Fed Ex and the USPS all have specific requirements for shipping liquids. Retailers, distributors and supply chains also require liquid products to have protection from potential leaks. In this exclusive webinar experts from Enercon Induction Cap Sealers and Selig Group Induction Liners provide insights on the industry’s best practices for packaging liquids for diverse…

Read More5 Tips Every Induction Sealer Operator Should Know

Is every container leaving your facility properly sealed? Is your team trained to setup, operate & troubleshoot your induction sealer? This new webinar focuses on tips & insights for optimizing your equipment to maximize productivity. Learn the keys to successful induction sealing: PLUS – GET FREE ACCESS TO:Getting Started with Induction Cap Sealing eBookSeal Integrity…

Read MoreCap manufacturers and packagers unite: pressure sensitive liners are on the way out!

Years ago, Bill Zito wrote about the disadvantages of pressure sensitive liners (PSL). Among the shortcomings were lack of tamper evidence, the inability to be used with liquid products and the absence of any type of moisture and oxygen barrier properties. Additionally, PSL are not recognized by the FDA as being tamper evident and have…

Read MoreInduction Sealing Conical Shaped Dispensing Cap Earns Hall of Fame Honor

For over a decade, Mendes Gonçalves, one of Portugal’s largest sauce producers, has relied on induction sealing to meet food industry regulations. Their Paladin brand is very well-known and includes mayonnaise, ketchup, mustard, BBQ and salad sauces in container sizes of 75ml to 1kg. One of their packages features a conical shaped cap which provides…

Read MoreCap Sealing Machine Increases Production Efficiency for Renfro Foods

Renfro Foods is a family-operated business experiencing tremendous growth. Since being named Vendor of the Year by Wingstop Restaurants, Inc., the Fort Worth, Texas company has pushed the capabilities of its packaging equipment to satisfy growing demand for their zesty sauces, salsas and relishes. The company first invested in induction cap sealing in 1995, when…

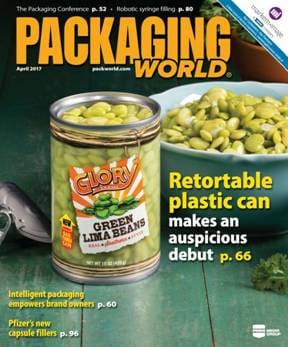

Read MorePlastic Can Induction Sealed after Seaming

As reported by Packaging World Magazine, McCall Farms of Effingham, South Carolina is creating a stir on store shelves with Sonoco’s new TruVue® can (To view a video of the new TruVue® can click here). Its clear design enables consumers to see the products inside the can before they buy. The innovative plastic container can be seamed at 500…

Read More