INDUCTION SEALING Featured Technical Articles

LEARN MORE All Technical Articles

Filter by Application

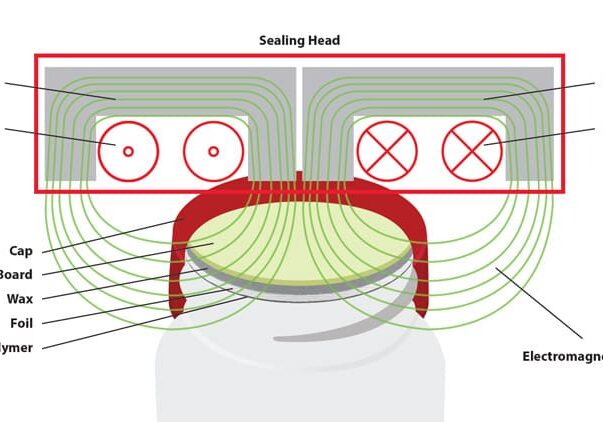

Are two sealing heads better than an “All-in-One?”

When you're sealing a wide range of containers, an "All-in-One" sealing head can be ideal. With sealing capabilities ranging from 20mm to 120mm, it can be a contract packagers best...

Hidden Benefits of Induction Seals

Are you doing enough to promote the benefit of your induction sealed packages to your customers?Most consumers view the induction seal as the final packaging barrier. It is the last...

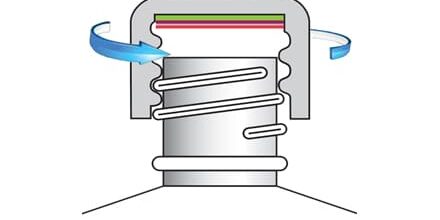

Induction Cap Sealing Basics

Induction sealing is a non-contact heating process that welds a foil laminate (called an inner-seal) to the lip of jars and bottles. The sealing process takes place after the filling...

Induction Foil Seals for Tamper Evident Packaging

The right inner seal for your container gives consumers confidence in safety and convenience. Inner seals provide tamper evidence and a hermetic barrier. Emerging technological developments include new designs that...

Induction Seals: Guardians on the E-Commerce Journey

Having products delivered directly to your door is a modern convenience. However, many packagers are still trying to optimize packaging through e-commerce channels. Leaking chemicals, spilled dishwashing liquid and compromised...

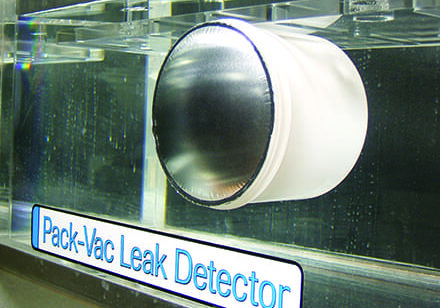

Tips and Techniques for Testing Induction Seal Leaks

One of the most frequently asked questions we receive is how to test for leaks. Unfortunately, there is not a simple answer to this question. There are no ASTM specifications,...

Are you maximizing the productivity of your induction cap sealer?

Finding the best cap sealer for your application might not be as simple as you think. With the introduction of several new models over the past few years, you have...

The Cheapest System Isn’t Always the Least Expensive

Shopping on price can be smart and risky at the same time. In most cases, Enercon is able to meet the needs of even the most budget-conscious purchaser. Occasionally, we...

Don’t Be Fooled by Kilowatts

There appears to be a misconception in the packaging industry concerning the relationship between the kilowatt ratings of induction sealing systems and sealing capability. While it is true that a...