Liner Options for Sealing Capped Containers, Bottles, & Jars

Cap Seal Liner Types for Bottles, Containers & JarsEvery product you see on a store shelf must be kept fresh, safe, and secure for consumers. Open a jar of peanut butter or twist the cap off a ketchup bottle – what’s the first thing you notice? That seal beneath the lid. A small but mighty component that protects your product and your peace of mind.

However, not all cap seal liners are created equal. Each type is tailored to suit the needs of different products, containers and industries. Some are perfect for sealing dry goods like spices, while others are manufactured to hold up to liquids like syrups or oils. Understanding these differences can help brands make informed choices for their packaging, keeping customers happy and products at their best.

Let’s explore the different types of cap seal liners, breaking down the uses and benefits of each, while discovering the vital design details that keep the products you rely on safe, fresh, and ready to enjoy.

An Introduction to Cap Seal Liners

Found beneath the caps of jars, bottles, and containers, these liners are a vital part of packaging security. Cap seal liners keep products safe from tampering, contamination, and leakage. They help maintain freshness and uphold the integrity of everything from food items to pharmaceuticals.

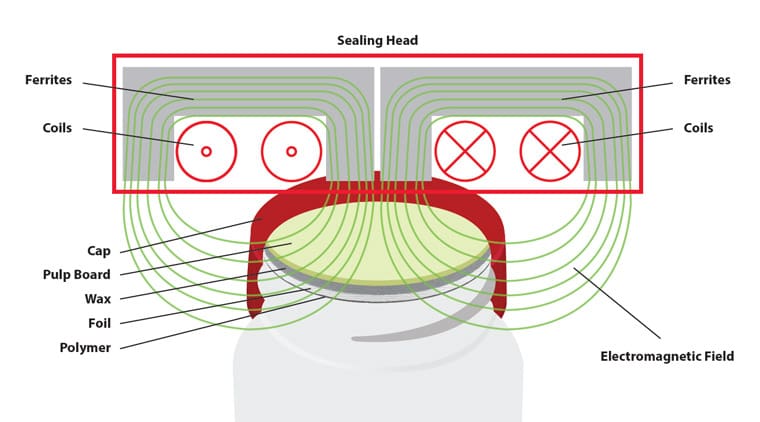

How are those liners applied? Specialized induction sealing machines use electromagnetic induction fields to create reliable hermetic seals. This process prevents leaks and provides tamper evidence, which is an essential part of building trust between a brand and its customers. Properly sealed caps reassure customers that the products inside haven’t been compromised during their journey from production to store shelves.

Types of Cap Seal Liners

When it comes to cap seal liners, there’s no one-size-fits-all solution. Different products and packaging needs require different sealing options.

Pressure-Sensitive Liners

Pressure-sensitive liners, as their name implies, adhere to the container’s surface when pressure is applied – no heat or sealing equipment needed. However, they do not provide tamper-evidence or prevent leaking of liquid products. And unlike an induction liner which creates an airtight hermetic seal, pressure sensitive liners are unable to protect product integrity from spoilage due to oxygen and moisture transmission.

Many packagers are moving away from pressure sensitive liners due to environmental regulations against polystyrene (PS) which is used in the construction of pressure sensitive liners. Because of these regulations there has been a significant reduction in suppliers of PS for pressure sensitive liners making them expensive and harder to source.

Induction Heat Seal Liners

Induction heat seal liners are the gold standard for creating airtight, tamper-evident seals. These liners rely on induction cap sealing machines to bond the liner to the container. Every induction seal liner includes a layer of foil and on the surface of the foil is a thin layer of polymer. During the induction sealing process, the magnetic field produced by the sealer heats the foil, which in turn melts the polymer so that it can bond to the rim of the container, resulting in a robust, leak-proof seal.

One-piece liners leave no residue inside the cap after sealing. Two-piece liners, on the other hand, feature a wax or paper backing, which stays inside the cap during use and supports resealing. These liners are ideal for liquid products, chemical containers, or anything requiring an impenetrable seal and additional barrier of protection.

Applications and Benefits

Cap seal liners are used in a wide variety of industries where product quality, freshness, and safety are top priorities. Their versatility ensures that they are a go-to solution for a variety of applications.

Industries and Products

The food and beverage sector frequently uses induction seal liners for products like sauces, condiments, syrups, oils, juices, dairy products, coffee, teas, peanut butter, nuts, snacks and dry spices. These liners keep everything fresh and protect the contents from spilling during shipping.

Pharmaceuticals also depend on cap seal liners to make sure medicine, syrups, and powders remain pure and tamper-free. In fact, the FDA recognizes induction sealing as an effective form of tamper evidence and requires two forms of tamper evident packaging on all over the counter (OTC) products.

Cosmetics, which often contain sensitive creams or liquids, use liners to prevent product contamination. Packagers of chemical products rely on induction sealing liners to prevent hazardous leaks and guarantee safe shipping and storage.

Benefits

Each type of liner brings unique benefits to the package. By offering an extra layer of protection, cap seal liners help manufacturers meet quality standards. They also support sustainable practices, as some liners extend the usability of packaging materials by preventing spoilage, thus reducing waste.

While heat induction liners are the gold standard for packagers by locking in freshness, extending shelf life, and preventing tampering, its important to select the right type of induction heat liner based on your specific application.

How To Choose the Right Liner

Selecting the right cap seal liner requires understanding both your product’s needs and the capabilities of each liner type. Making a mistake with the liner can result in leaks, contamination, and poor customer experiences.

Product Type

Is your product caustic? If it is, the induction liner you select will need to be able to withstand contact with the product. For example, a universal liner that is designed to work for a wide variety of applications may not have the properties required for caustic applications. Does your product off-gas? If so, you’ll likely need a vented liner that will allow the container to breathe to prevent bloating and panel distortions of the container.

Liner Material

Not all liners work well with every container. Most induction sealing applications involve plastic caps and containers. The liner material must be compatible with material of the container for proper bonding. For glass containers there are specialty liners specifically designed for glass. However, finishes on glass can vary so it’s very important to conduct comprehensive testing in a lab with induction sealing experts from Enercon. And, while it’s possible to seal a metal cap, caution must be taken as the cap will heat up as it goes through the induction field.

Consumer Experience

The type of liner you select is also dependent on what you want your consumers to experience. Pharmaceutical companies opt for tamper evidence liners which leave evidence of the seal once it has been removed. Beverage packagers prefer clean peel liners that do not leave a residue on the lip of the container. Food packagers select induction liners that will ensure product freshness and extend shelf life. Many packagers opt for a liner with an additional tab that makes it easier for consumers to remove the seal. Petroleum and Chemical packagers rely on rugged induction seals that prevent hazardous leaks. And two-piece induction liners are used when the packager wants the consumer to have a secondary seal left in the cap after the primary seal is removed. Examples of this include OTC products and chemicals.

Conclusion

Induction heat seal cap liners provide tremendous packaging benefits for a very small investment. They are very easy to use, ensure product integrity, provide tamper evidence, prevent leaks, and extend product shelf life. With the move away from pressure sensitive liners, packagers are making major gains in consumer trust and package performance. The world of cap seal liners is constantly evolving to meet the needs of brands, packagers and consumers. Induction sealer experts at Enercon can help you ensure you always Achieve a Perfect Seal™ by ensuring you have the right liner and induction sealer set up for your application.