INDUCTION SEALING Featured Webinars

ON DEMAND Webinars

Filter by Application

Best Practices for Sourcing Caps, Liners & Equipment for Induction Sealing Success

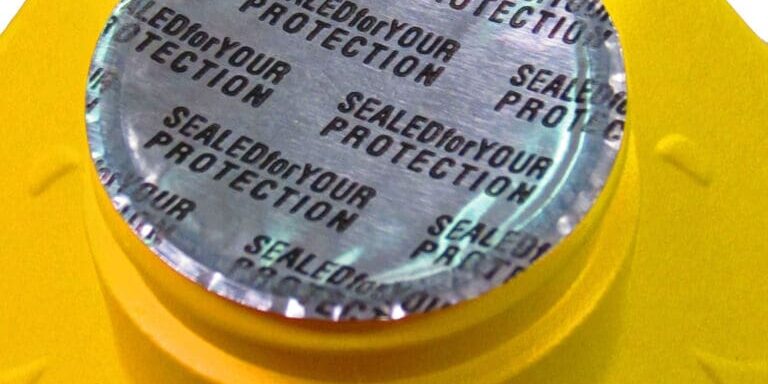

Induction sealing is a wonderful technology that prevents leaks, provides tamper-evidence, and increases shelf life. In this new roundtable discussion, experts in induction sealing materials and equipment share their experiences...

What is E-Commerce Packaging & How Do Cap Sealers Play a Role

Companies like Amazon are raising the bar when it comes to packaging for online retail. What does this mean for your brand and the future of packaging? Enercon & packaging...

New Super Seal™ Pro Cap Sealer with Integrated Intelligence to Achieve a Perfect Seal™

From the brand that’s induction sealed billions and billions of containers around the world comes the most intelligent cap sealer ever made. In this webinar, you’ll discover an amazing new...

Optimize Your Caps, Liners & Capping for Induction Sealing

Get an in-depth perspective of the relationship between liners, caps, cappers & sealers. Discover the critical interactions for successful cap sealing when designing a package. Expert panel will offer their...

Nutraceutical Packaging Tips & Trends for Caps & Sealing

Demand for Nutraceuticals is on the rise & packaging is playing a key role. Caps & induction liners ensure product integrity, safety, & freshness in consumer friendly packaging. With so...

Tips for Accurately & Safely Packaging CBD & Cannabis Products in Jars & Bottles

Discover best practices for packaging medical & legal recreational cannabis. Set up your packaging line for ease of use, accuracy, reliability & quick changeover capabilities. In this 60-minute webinar, packaging...

Inspect, Detect & Reject Your Way to Increased Cap Seal Productivity

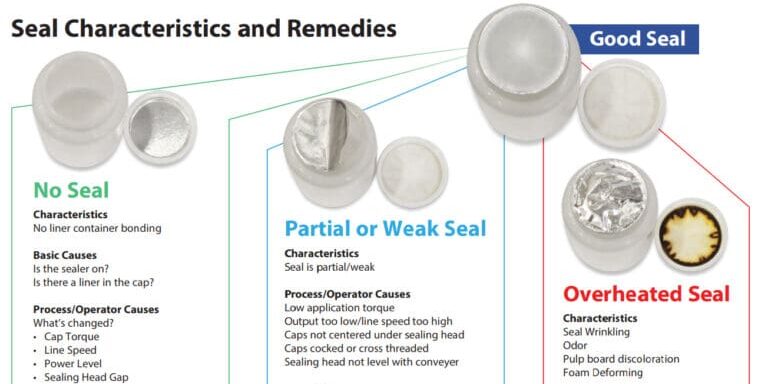

You’ve chosen an induction sealer to prevent leaks, provide tamper evidence and preserve product freshness. It's a key component of your packaging strategy and your team should be well trained...

Induction sealing with vented liners prevent leaks & maintain package integrity

Consumers equate product quality with packaging appearance. That’s why great products deserve smart looking and functional packaging. When packaging fails to retain its integrity on the store shelf, consumer confidence...

Boost Induction Cap Sealer Productivity & Reduce Rejects

Master Your Induction Cap Sealer's Features & Options Learn how to control and monitor sealing energy, use inspection to improve quality control, and why electrically integrating your cap sealer is...