New Cap Sealer Tools Drive Productivity for Pharmaceutical, Food & Chemical Packaging

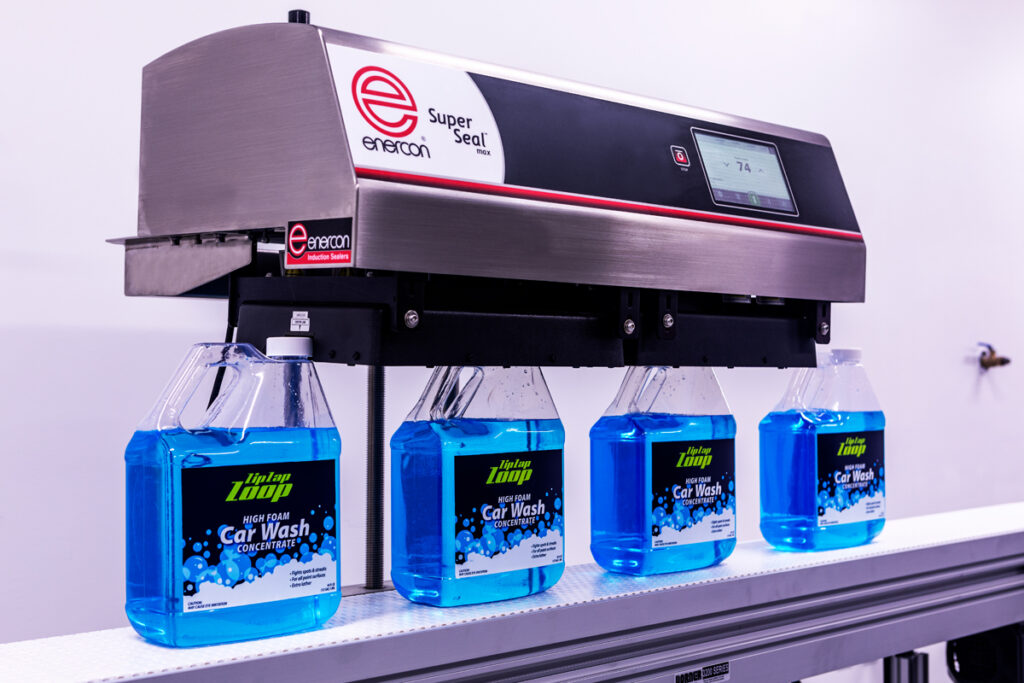

Enercon’s new Super Seal™ Pro & Super Seal™ Max cap sealers create hermetic seals on a wide variety of cap and bottle configurations to prevent leaks, provide tamper evidence and ensure product freshness. However, these new sealers go far beyond the capabilities of their predecessors as they are loaded with additional tools to improve productivity, quality and control.

Whether you’re just starting out in packaging or have high performance integrated lines, Enercon has unique tools to ensure your success. From advanced packaging lines for healthcare and pharmaceutical products, to start-up co-packing lines with a new team, you’ll find the feature set of these new sealers make it remarkably easy to Achieve a Perfect Seal™.

Pharmaceutical & Healthcare Packagers

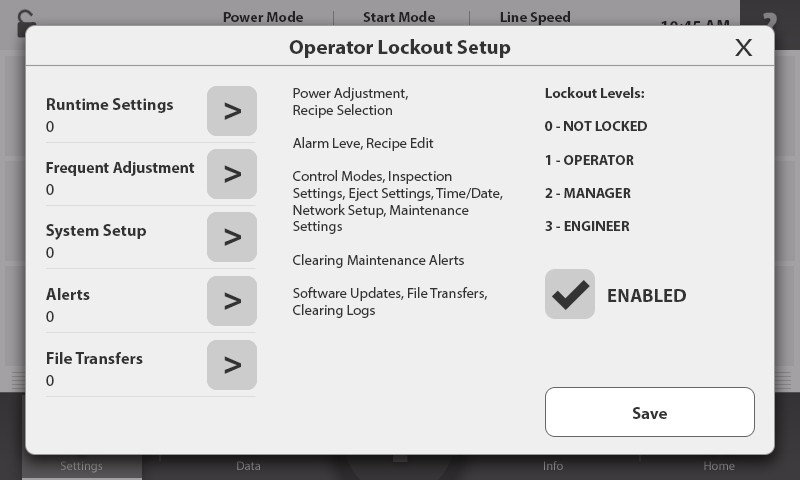

- Supervisory password protection ensures only authorized personnel can modify critical settings, supporting regulatory compliance.

- Operator lockout prevents unauthorized changes during production, reducing risk and maintaining process integrity.

- Detailed fault diagnostics help quality assurance teams quickly identify and resolve issues, minimizing downtime.

Chemical and Food Co-Packers

- Recipe storage & management for 50 unique recipes enables saving and recalling sealing parameters for different products, streamlining changeovers and ensuring consistent results.

- Remote control modes enable centralized management of multiple sealers across packaging lines.

- Maintenance reminders keep equipment running smoothly with proactive alerts.

Advanced Packaging Lines

- Network control & monitoring is compatible with all major industry protocols, allowing sealers to be part of a unified production ecosystem.

- Integrated cap inspection & container rejection enhances quality control

Packaging Teams with New Employees

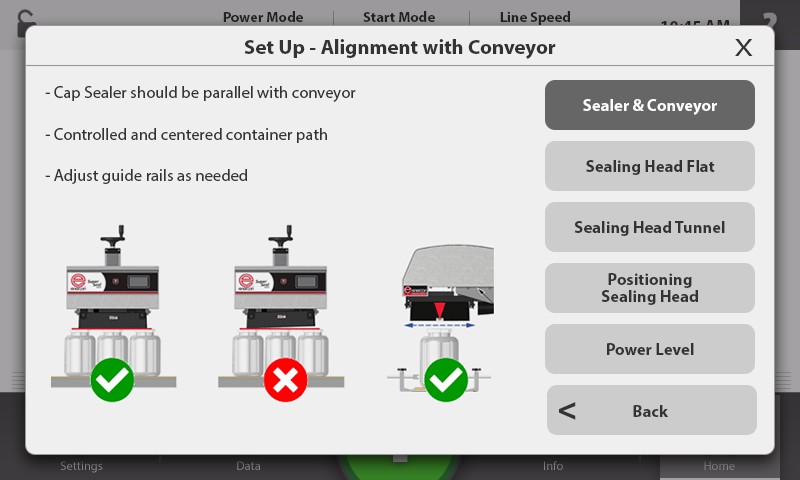

- Intuitive 7” touchscreen interface simplifies operation with clear visuals and step-by-step guidance.

- Integrated setup & troubleshooting help provides on-screen instructions and visuals for conveyor alignment, container positioning, and fault resolution.

- QR code support access directs users to Enercon’s online resources, including videos and how-to articles, for additional help.

All Packagers

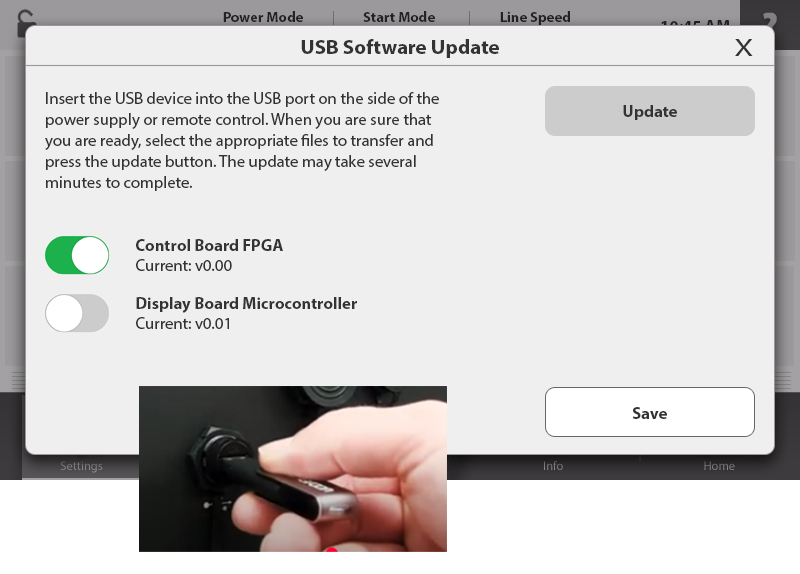

- USB port for software updates & diagnostics enables easy uploading of new features and downloading of fault logs for rapid troubleshooting and support.

- Advanced microprocessor control monitors operating parameters and captures critical data should a fault occur.

- Detailed fault logs, along with bottle & foil counts support production tracking and efficiency.

To see which features will benefit your operation, contact Enercon for a custom review of your packaging line requirements and learn how Enercon’s innovative technology can help you Achieve a Perfect Seal™.