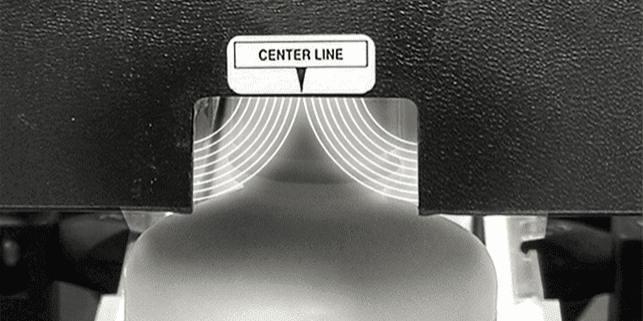

Tunnel Sealing Head

Tunnel sealing heads are generally used in two situations, when the foil liner diameter is less than 53mm and for closures where there is a larger gap between the liner and the top of the closer.

Examples of this include child resistant caps and many dispensing caps. The tunnel sealing head was developed to address these concepts and is typically used in two situations. A tunnel sealing head allows us to most efficiently seal the package by directing the induction field from the top and sides of the container. Taller closures such as sports caps, push-pull, Yorkers and others place the foil relatively deep in the cap. So, the induction field is directed from the sides to efficiently seal the container.

Enercon also offers a flat sealing heads and a special sealing head known as our All-in-One sealing head which allows you to seal a range of closures from 20mm up to 120mm all with the same sealing head.

Please consult with Enercon if you have questions on which sealing head is best for your operation.

KEY FEATURES Tunnel Sealing Head

-

Designed for containers where there is large distance between the top of the cap and the induction liner

-

Energy efficient design directs sealing energy from the top & sides to optimize induction field

-

Available in standard, wide & deep designs