Induction Cap Sealing Head Design

Enercon's ingenious cap sealing head designs optimize induction fields to seal your containers in the most energy efficient and reliable way possible.

When you purchase an Enercon Super Seal™ induction cap sealer our team expertly matches the power supply, interface and sealing head to meet your specific application requirements. Our engineers have developed a series of unique induction sealing heads that provide you with the most energy efficient induction sealing solution possible.

Packagers sometimes overlook the importance of induction sealing head design. While the power supply plays a significant role, the efficiency of your cap sealing operation depends on the design of the sealing head. The secret to creating fast, efficient, and consistent seals is the energy transfer from the cap sealer power supply to the induction sealing head and into the foil liner. If you don't optimize the induction sealing head design, increasing power only wastes energy.

There are a number of key application variables taken into consideration when Enercon recommends an induction sealer configuration. These variables include line speed, cap diameter, cap type, and liner type. When any of these variables change you should consult with Enercon to see how your current sealer is equipped to handle the new set up. In some cases no changes to your set up are required. In other cases an adjustment to the power level or line speed will ensure successful sealing. It is also possible that your operation would benefit from a second sealing head designed to better accommodate your additional application.

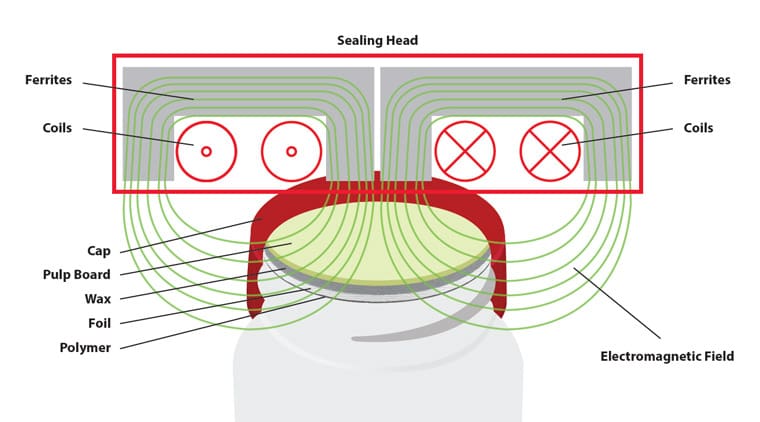

The illustration below depicts the electromagnetic field created by a standard flat sealing head design. Below that are images of how our tunnel & deep tunnel designs modify the field so that it maximizes contact with the foil liner for efficient heating. Learn more about how the types of caps impact selection of optimal induction sealing head.

For more information on induction sealing heads please contact us.

KEY FEATURES Induction Sealing Heads

-

Application variables including cap style, liner size, liner style, container shape & line speed affect sealing head choice.

-

Each version of Enercon's high efficiency sealing heads create a unique induction field to optimize sealing results.

-

Enercon engineers & application experts can recommend the best sealer for your application.