Enercon Improves Upon Electrode Performance

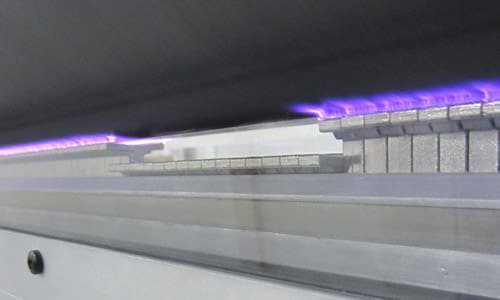

MENOMONEE FALLS, WI – Enercon Industries Corporation has improved the appearance and performance of their 1/4 inch stainless steel segmented electrodes. This electrode innovation provides fine width lane control with minimal expansion and warpage during operation of the corona treating system. The new Enercon design assures a precise, uniform air gap across the web width for a consistent, high-level of treatment throughout the production run. This electrode is especially applicable to film extrusion lines.

Enercon Industries Corporation, headquartered in Menomonee Falls, WI, is a major manufacturer of equipment for the plastics and packaging industries. The company supplies custom built bare-roll, covered-roll, and universal-roll corona treating systems; 3D plasma treaters for the plastics and rubber industries; and induction cap sealing systems for food, dairy, chemical and pharmaceutical packaging.

Release date: 3/1/1998