Metallized Film Adhesion: Processing & Converting with Surface Treatment

Metallized film presents adhesion challenges to both film suppliers and converters. Today, new developments in surface treatment are creating competitive advantages by extending surface energy stability on metallized film.

What metallized film converters should know

Both the metallized film supplier and converter are at the mercy of the physics involved with dyne levels. Dyne level reducing factors such as time, humidity, additives and contamination all play a role in the films adhesion. Controlled storage facilities and timely inventory procedures certainly help, but with all these uncontrolled variables at play its clear that a metallized film supplier cannot reliably provide convertible material 100% of the time.

The industry’s best practice is to eliminate dyne level decay issues by bump corona treating the material with Enercon’s high definition corona treatment at the time of converting to create a fresh clean surface ready for bonding. This puts the converter in control of the substrate surface energy and value added process.

Learn more about surface treating and metallized film converting.

What metallized film processors should know

To achieve a brilliant, blemish-free metallization coating, raw substrates must be free of surface contamination, such as migrating additives, dirt, dust, and other contaminants. Surface treatment can effectively remove organic debris from the surfaces of packaging materials such as films to retain their metallization layer and provide barrier properties at designed and acceptable level.

When processing metalized film, a layer of metal is deposited on plastic films using several different methods, ranging from vapor deposition to electroplating. Some of the variables that can affect the adhesion of the metalized film are surface differences between the type of film substrates, the potential variations of film characteristics within different substrate families, variations with use of the same substrate between vacuum metallizing chambers, and any possible variations within an end use application, even when using an identical film. The way the film is processed must be put into consideration when surface treating the film for improving adhesion.

There can be significant differences among these metallizing substrates. An initial consideration is their respective surface polarities, either inherent or pre-conditioned. In the case of the latter, a non-polar surface can be prepared to chemically and molecularly bond to the deposited aluminum layer by oxidizing the surface. This is typically accomplished by contributing oxidation, peroxides, alcohol, ester, ether, and aldehyde functional groups which will bond well to aluminum depositions.

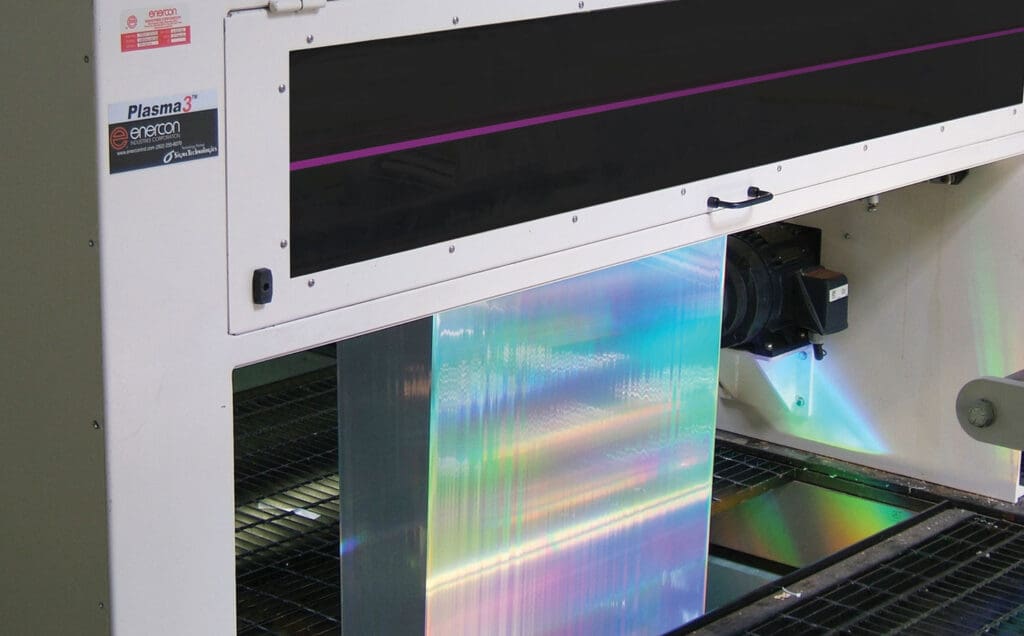

Enercon offers a variety surface treating options for metallized film ranging from high-definition corona to atmospheric plasma, Plasma3™. Surface treatment prior to metallization can significantly improve surface adhesion performance to meet these requirements. Plasma treatment conditions can be developed such that surface cleaning, chemical surface functionalization and micro-roughening of the polymer surface are achieved.

For more information on the latest atmospheric plasma surface treating solutions for metalized film applications watch this on-demand webinar.