Embossed Film Corona Treating Design Minimizes Pinhole Potential

Selecting the right corona treater design for your specific application is always key to success. Since Enercon offers an assortment of configurations including metal electrodes, ceramic electrodes and a variety of roll covering options, we can offer you unbiased recommendations on which design is best for your application.

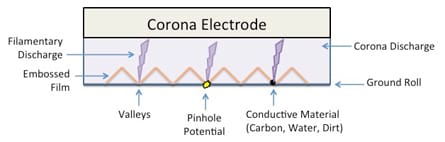

When treating embossed film, it is important to recognize that microscopically the film has as series of peaks and valleys. These valleys create a special set of circumstances when it comes to interacting with corona that may lead to pinholing.

- The valley is in contact with the ground roll creating the shortest path to ground

- Film is thinnest at the valley which can create a weak point

- Filamentary corona discharges will be attracted to the shortest path to ground

- Filamentary discharges deliver treatment surges greater than the prescribed WD/inch

- Any conductive debris in the valley (carbon, dirt or moisture) will attract discharges

It is well known that metal electrodes produce a more filamentary discharge than ceramic electrodes. For some applications, this can be an advantage. However, for embossed film, filamentary discharges can lead to pinholing.

Enercon has developed a special ceramic electrode treater station design that minimizes filamentary discharges and also expertly manages the films’ exposure to watt density per square inch without sacrificing treatment levels. This design has been proven in our surface treating laboratory and is in operation at numerous embossed film lines around the world.