Improve Composite Bond Strength With Plasma Treatment

Atmospheric plasma treaters can significantly increase the interfacial adhesion characteristics of composite structures. The types of composite structures than can benefit from atmospheric plasma are emerging rapidly. Many new plastic nanocomposites have offered valuable properties, such as heat resistance, chemical resistance, structural/stress strength and weather resistance. As a low temperature solution, plasma treaters offer an economical and highly effective means to achieve improved bond strength of nanocomposites to each other and to virgin materials.

Types of Composites

Plastic nanocomposites (PNC) are composed of nanometer size inorganic particles which are dispersed in a polymer-based matrix. PNCs contribute structural reinforcement to these applications by virtue of their aspect ratio, large surface area, and the molecular interaction between the nanoparticle and the blended matrix. Many advanced composites now use pure carbon fibers, as they are much stronger and lighter than glass fibers. They are increasingly being used instead of metals.

Hollow carbon nanotubes (CNT), that are thousands of times smaller in diameter than carbon fibers offer uniform surface resistivity. This uniformity reduces the current or static-induced issues associated with carbon fiber-filled composites. This is a critical consideration when integrating carbon nanotube composites into automotive applications such as fuel system components, and for electrostatic coating and painting processing equipment.

Composite Surface Adhesion

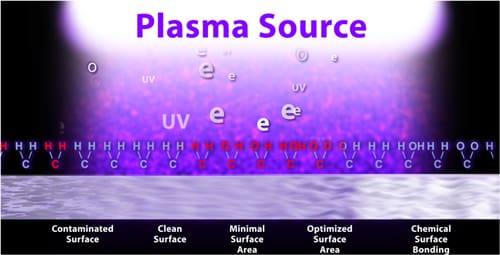

The interfacial adhesion between nanocomposites, and between nanocomposites and virgin materials, is determined by the surface and interfacial free energies of each respective material. Modification of the surface to create greater surface area, in addition to imparting free radical surface effects to create new surface bonds with introduced chemical functionalities, are primary approaches for maximizing interfacial adhesions. Research on nanoparticle, carbon, glass, cellulose and aramid fiber surfaces and their surface chemistry, surface energies, and chemical reactivities relative to epoxy, polyurethane, BMI, polyimide, polycarbonate, polyamide and vinyl ester matrix systems has led to experimental surface modifications by plasma (air, flame, chemical) systems at atmospheric pressure.

The critical objectives are to first optimize the level of adhesion between the nanoparticle reinforcement material and matrices using surface treatment techniques, without changing the nanoparticle reinforcement or matrix. The second critical objective is optimization of the interfacial adhesion between the composite with another composite or virgin material. Since thermoset and thermosoft matrices compose most composite structures, low dwell time, low temperature atmospheric plasma surface treatment regimes are expected to offer the most wide-ranging solutions for improving interfacial adhesion.

As a low temperature process, atmospheric plasma presents a cost-effective technology to clean both particle and organic contaminations at attractive processing speeds because of their low capital and operating expense, in addition to their high density surface reaction capabilities. Atmospheric pressure ion plasma bombardment devices are true non-thermal plasma systems which deliver a stream of high velocity ions to substrate surfaces. The source discharge produces a stable, homogeneous and uniform plasma stream using air or various gases under pressure, passing between electrodes which are well upstream of the discharge orifice.

For some applications flame plasma systems may be appropriate. The surface of materials are made polar as species in the flame plasma affect the electron distribution and density on the surface. This polarization and functionalization is made through reactive oxidation of a surface. Flame plasma treatment’s extensive oxidation, due to reactions with OH radicals in the flame, results in a highly wettable surface which is relatively stable upon aging.

To determine which surface treating technology is best for your application, Enercon offers complimentary trials in our surface treating laboratories. Please contact us for more information.